Kistler is your competent partner for sophisticated measuring applications in the field of R&D – e.g. for vehicle testing and aerospace testing; for monitoring processes in industrial manufacturing; for condition monitoring of sensitive infrastructure in the public sector; for protecting roads, rail and road users. Digital solutions include software applications that help you manage big test data.

Applications

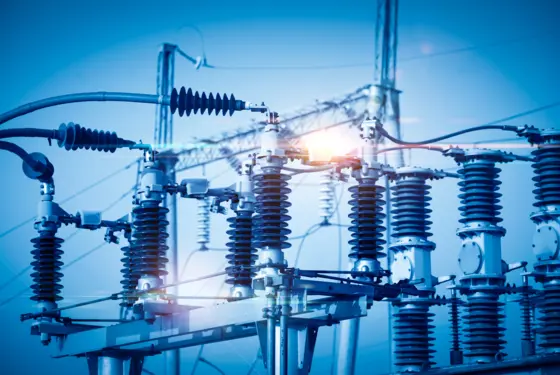

Innovative measuring technology for industrial applications and monitoring of public infrastructureIndustrial solutions

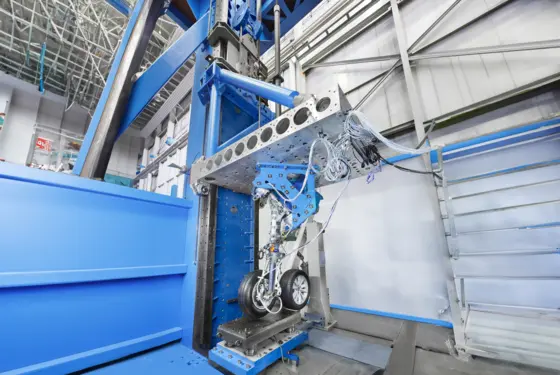

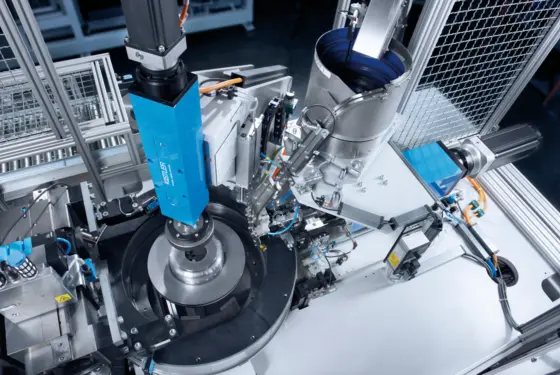

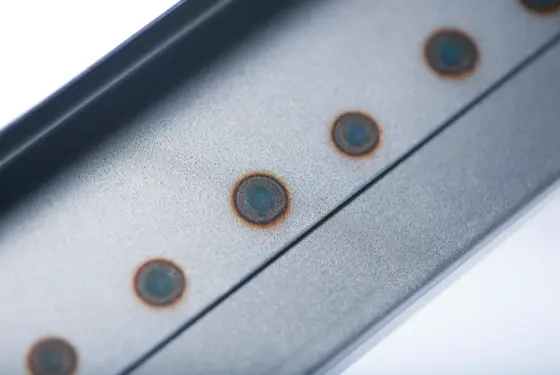

Advanced manufacturing

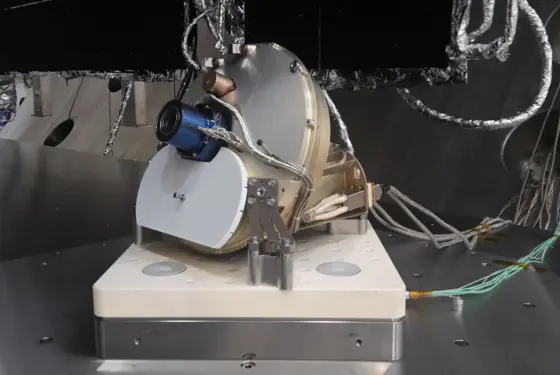

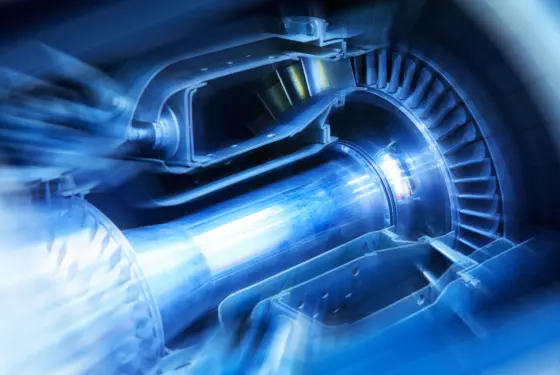

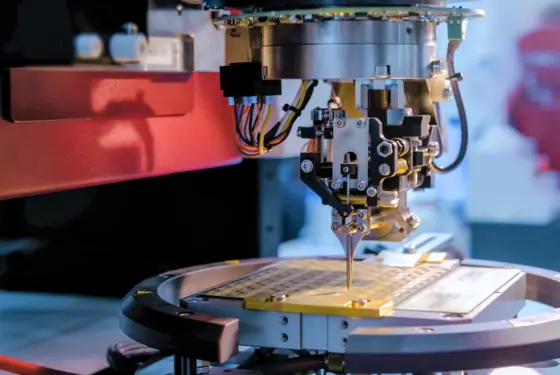

Research and development solutions

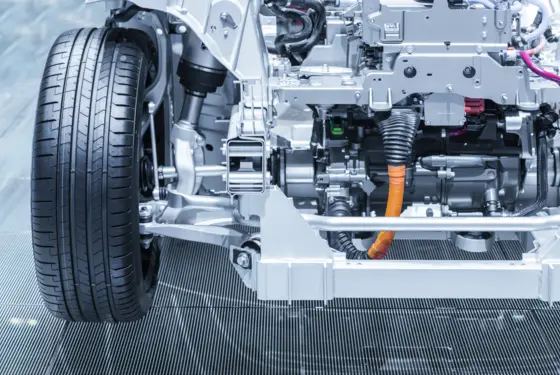

Automotive

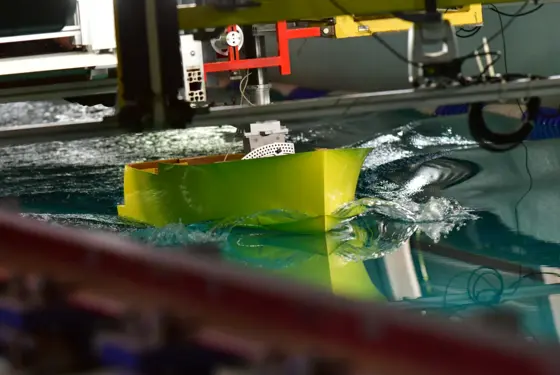

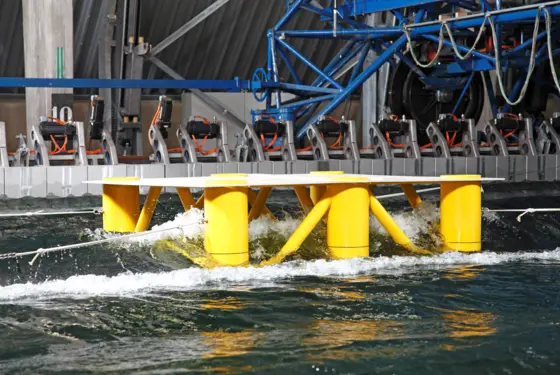

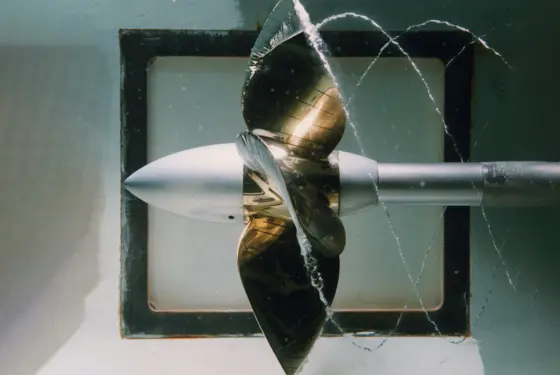

Maritime

Biomechanics and sports

Traffic and infrastructure solutions

Need a consultation?

Our experts are just a click away.

![Composite – quality assurance by RTM process monitoring and control [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/kistler_composite_quality_assurance_by_rtm_process_monitoring_and_control.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/936-370.webp)

![Vibration testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/vibration-testing-16599.webp)