May 21, 2025

Success Story

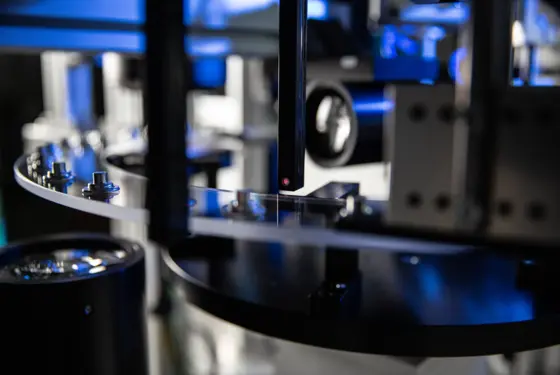

Gait analysis: a Kistler force plate supports a gait lab at ONCE University School of Physiotherapy

In the gait lab at ONCE University School of Physiotherapy, a force plate from Kistler supports gait analysis, diagnosis and clinical research.