Modular assembly and testing systems for automated production are the key to converting and upgrading production lines – sustainable solutions that let you react quickly to changes in demand so as to ensure profitable operation. Kistler supplies a diverse range of assembly, measuring and testing systems for industrial automation and digitalization. Our solutions cover joining, assembly and inspection processes for complex parts and products. With our modular, highly integrated turnkey solutions, manufacturers can gradually step up the automation level of their production – including quality assurance. The flexible response to changing market conditions!

Modular assembly and testing systems for industrial production

We also offer an extensive portfolio of highly flexible modular testing systems for quality monitoring of complex fastening processes. The key to quality assurance in fastener assembly – one of the most frequently used joining processes in almost every area of industrial production.

Our solutions are underpinned by application know-how gained from over 60 years' experience with piezoelectric measuring and testing technology for joining and assembly processes. We are experts at designing diverse, smart combinations of efficient technologies, systems and components – and we know exactly how to integrate them into your systems.

From consulting and development through to commissioning – Kistler offers everything from one single source:

- Optical testing and sorting machines for punched parts (mass production and series manufacture)

- High-performance hardware and software for quality assurance in fastener assembly

- Automated test stand systems for electrical drives, research and development, and end-of-line (EOL) applications

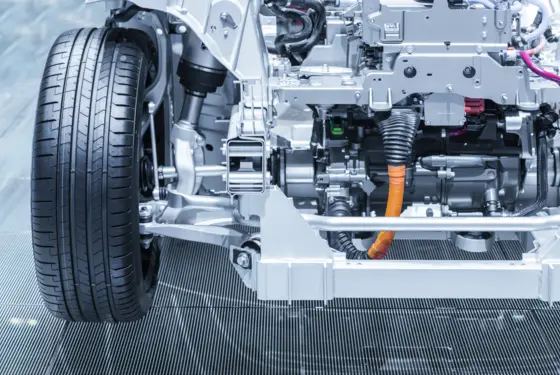

- Intelligent assembly and test stations for joining and press-fit processes in the automotive and electromobility sectors

Our unique Application Centers – such as the Kistler Joining Competence Center (JCC) – offer you the chance to work with us on developing and/or testing your individual application under real-life conditions.

We will be by your side on your journey into the future of industrial manufacturing – with individual, sustainable solutions to automate and digitalize your production throughout the value chain. You're welcome to contact us right now!

Automated testing systems for small, mass-produced and series parts – with imaging

Automated optical measurement, testing and sorting machines can be integrated into the production line as modules or operated as standalone solutions. Our testing systems include high-resolution optoelectronic sensors, digital camera systems and laser triangulation sensors to deliver efficient end-to-end quality monitoring. As a complement to test automation, our laser marking system for continuously produced series parts (marking-on-the-fly) ensures 100 percent product traceability.

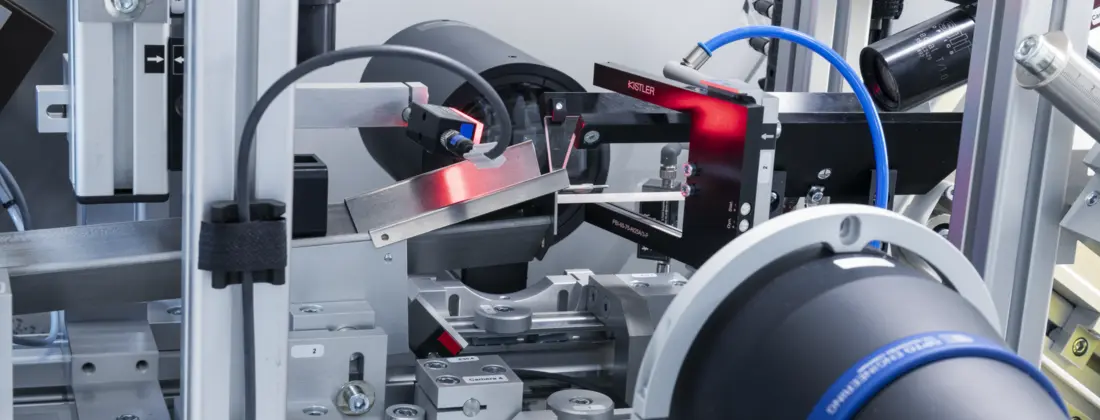

Testing systems for quality assurance in industrial fastener assembly

Reliable processes in fastening technology – thanks to our fastening tool testing and calibration systems, and test stands to determine the mechanical properties of fasteners. To complete the range, we offer portable measuring instruments to test fastening processes before, during and after assembly work: your guarantee of the highest standards for assembly and quality testing of bolted joints.

Automated testing systems and test stands for electrical drives

We offer modular testing systems and test stands for semi- and fully-automated quality assurance tests on electric and high-efficiency motors in R&D: these are scalable, turnkey solutions that we manufacture to customers' specifications. The same applies to our EOL (end-of-line) test stand systems for production facilities. High-precision measurement technology synchronously captures electromechanical measurement signals. Users can perform both online and offline evaluations to determine efficiency, dynamics and stability at every operating point.

Modular assembly and test station – joining and press-fit cell – Smart Single Station

Modular assembly and test stations such as joining and press-fit cells from Kistler: the key to automated monitoring, control and optimization of assembly operations that require force-displacement monitoring. We offer customized, highly integrated configurations for every automation level. We develop our Smart Single Stations (SSTs) specifically for production sectors such as automotive and electromobility, where maximum product quality and 100 percent traceability are critical. SSTs are available as standalone solutions or in versions for integration into existing systems.

Joining Competence Center (JCC) – Application Center

The Joining Competence Center (JCC) is one of several Application Centers we operate throughout the world. As your development partner for new automation applications, our JCC offers you the chance to test your specific requirements under real-life production conditions: then, we can work together to develop solutions that are precisely fit-for-purpose.

Featured products