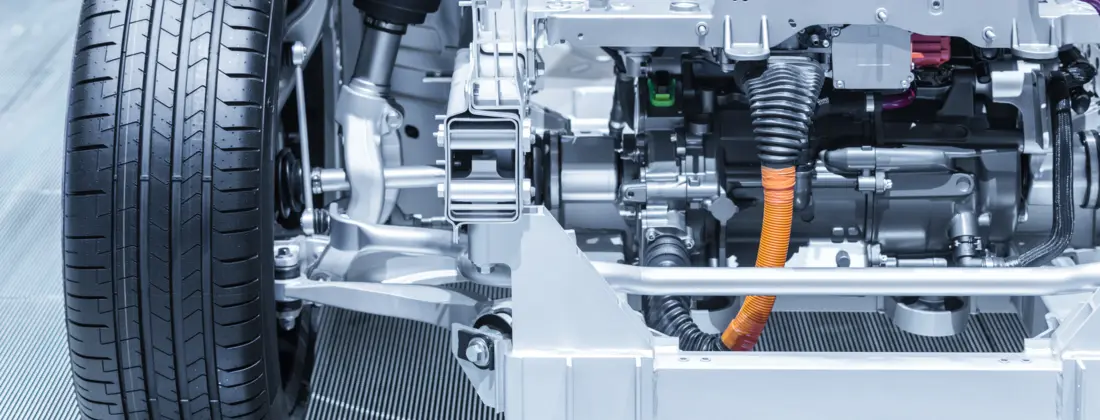

Torque sensors from Kistler can reliably accomplish friction and efficiency tests of all types. Calculating the efficiency of pumps, transmissions and engines requires a comparison of input and output power. Torque sensor technology from Kistler allows to calculate the power exactly from the input moment and the measured speed.

In addition to efficiency testing, Kistler torque sensors are also used to measure friction coefficients: initial quality control for end-of-line powertrain testing is just one example of this application.

Advantages of friction and efficiency testing with Kistler:

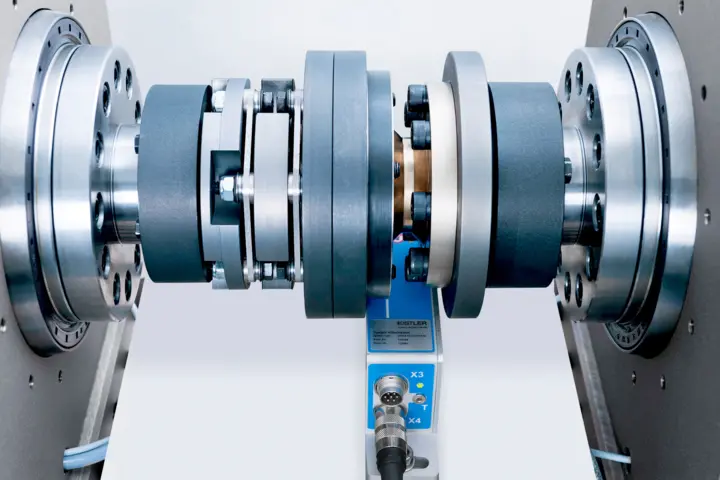

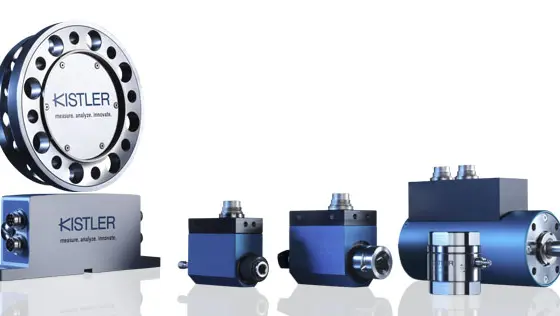

- Flange or shaft sensors fit flexibly into the test stand

- Parallel measurements of two torques using dual-range sensors

- Exact results thanks to piezoelectric sensors

- High-precision torque sensor technology for reliable friction and efficiency testing.

![Product Line for Process Instrumentation and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/300-629e.webp)

![Torque Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-275e.webp)