Jul 8, 2025

Media release

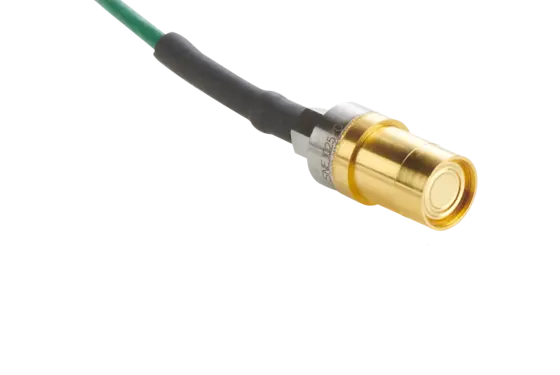

Optical sensor for measuring vehicle dynamics in motorsport – Correvit KiMotion Racing

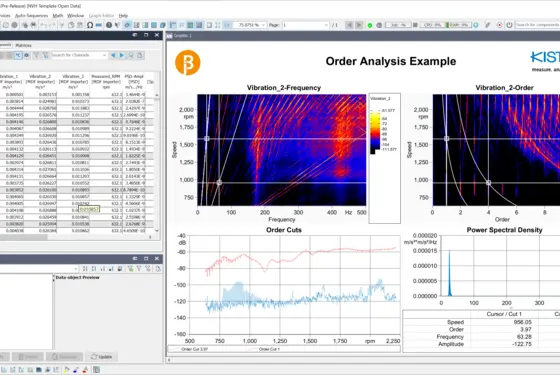

The new optical sensor Correvit KiMotion Racing sets standards in the measurement of vehicle dynamics under extreme loads in motorsport.