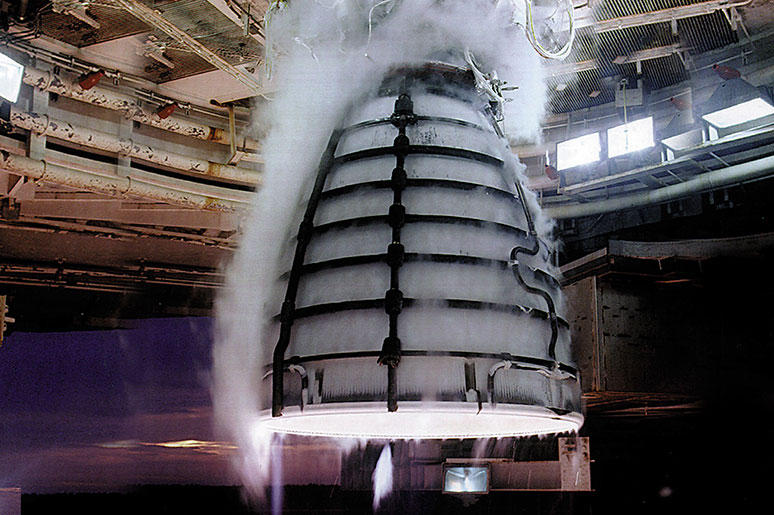

Thrust characterization

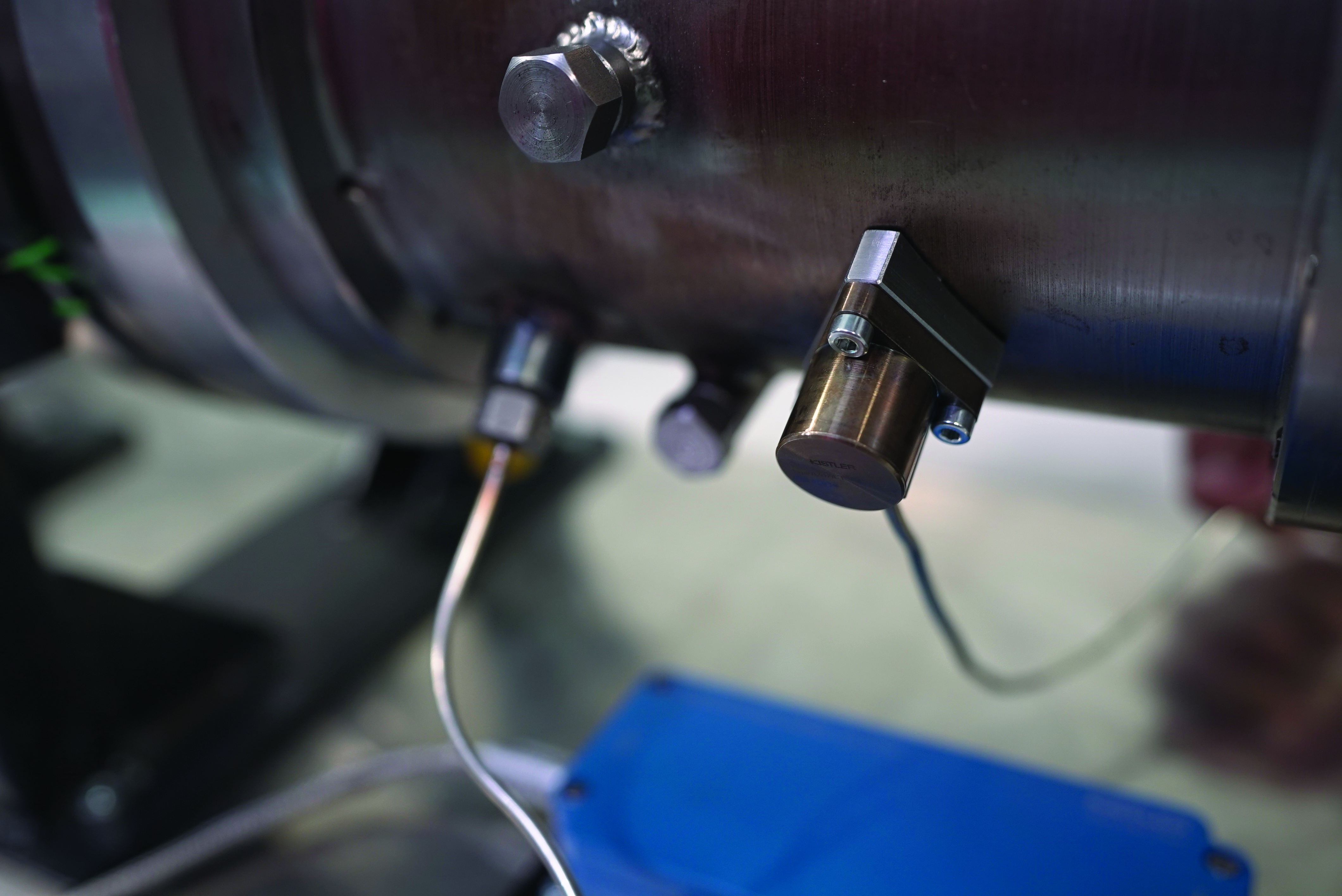

Fuel efficiency for both solid and liquid rockets is a major concern for rocket engine designers. Characterizing the thrust provides a clear understanding of how much power can be produced with a given nozzle design. This allows engineers to compute the specific impulse of the combustion material and study the different phases of ignition, burn-in and switch-off. Application specific 6-axis piezoelectric (PE) dynamometers are ideal for such investigations.

This approach also provides an in-depth understanding of the injection and mix of fuel components, ignition time, imbalances, and combustion: essential knowledge to verify the reliable performance of a rocket engine and drive the development of propulsion technologies. Piezoelectric pressure and acceleration sensors from Kistler span the extreme range of ultra-high temperature stability and dynamics required to tackle the challenges encountered in extreme thrust chamber environments. Based on the request we can provide customer-specific dynamometers (force plates) through our dedicated Kistler Custom Product Lane team (CPL).

![Space brochure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-096e.webp)

![Space brochure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-096a.webp)

![Airbus [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-294e.webp)

![Smooth performance near absolute zero [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-420e.webp)

![AS9100 D certificate granted to the facility of the Kistler Group site in the U.S. [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-240e.webp)