Unique cavity pressure sensors for plastics injection molds

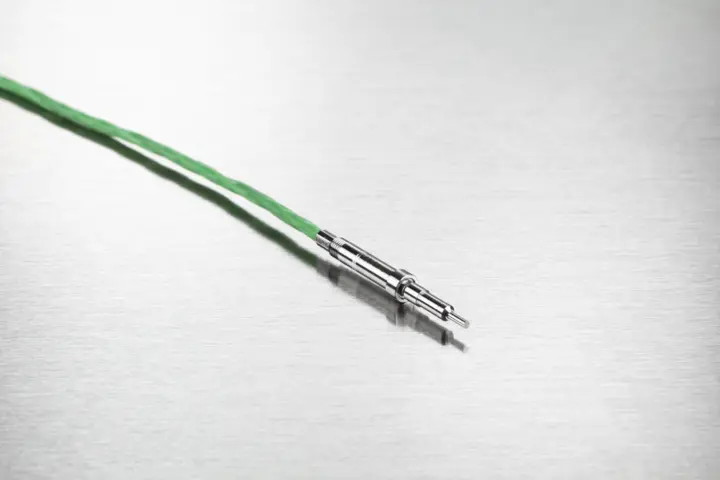

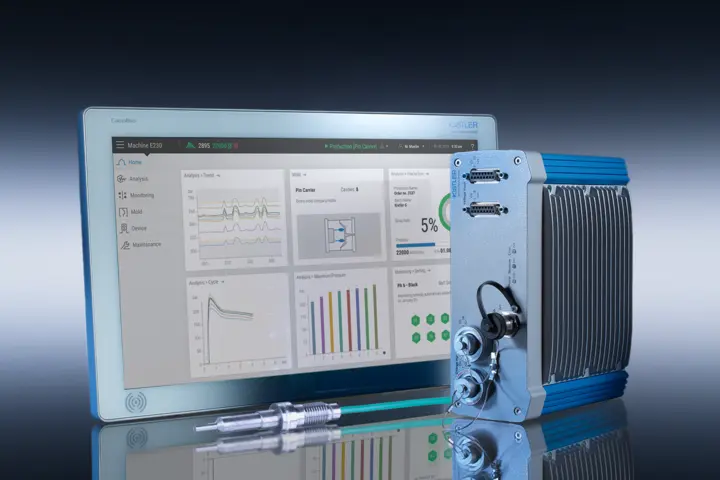

Cavity pressure provides a direct criterion to determine part quality in the production of plastic components in the 3C electronics industry. In addition to machine data, it plays a key part in transparent process monitoring. To achieve this objective, we offer an extensive portfolio of high-precision pressure sensors to equip a varied range of single as well as multi-cavity molds. This also covers a choice of unique sensors that are particularly designed for plastics injection molding in the 3C electronics manufacturing, for example:

- High-pressure sensors to measure cavity pressure up to 2,500 bar

- pT-sensors to measure cavity pressure and temperature simultaneously

- Contactless cavity pressure sensors to meet the high surface quality requirements and are easy to maintain

![Process monitoring and control [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-605e.webp)

![Sensors and systems for Quality monitoring and process control in injection molding [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-112e.webp)

![AkvisIO - process data management [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-610e.webp)