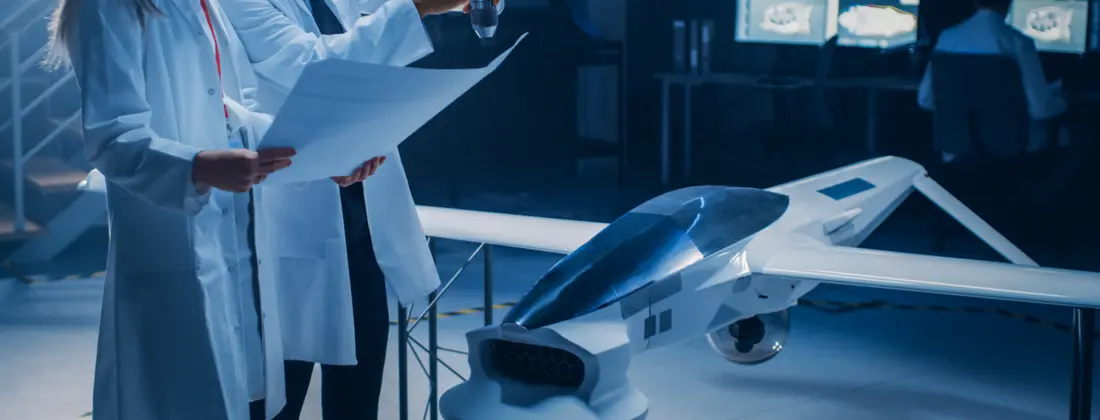

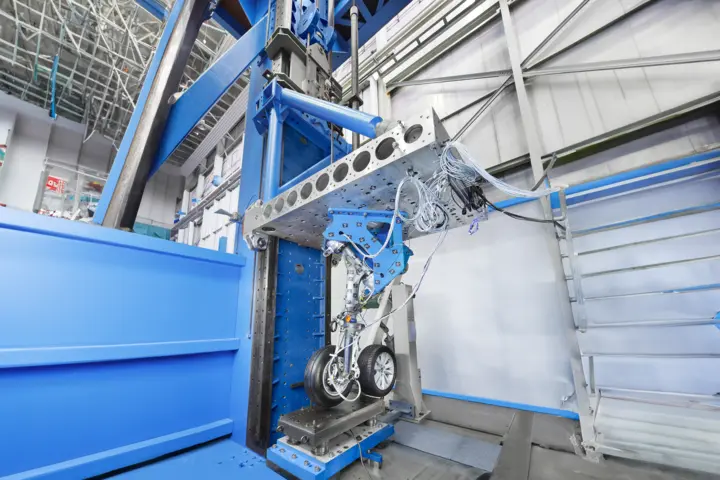

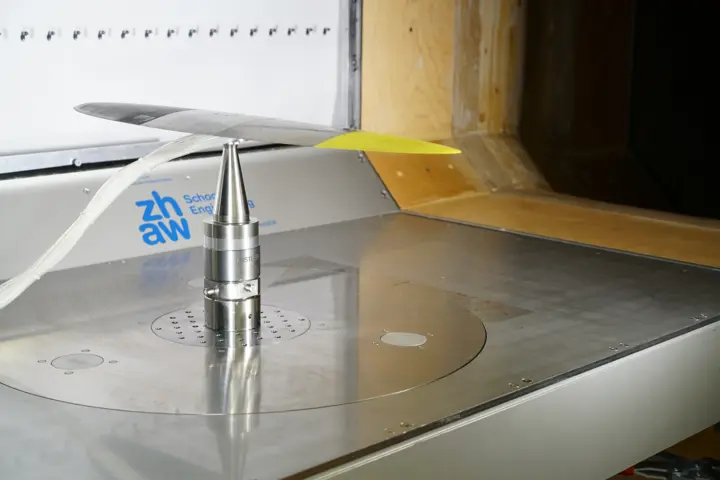

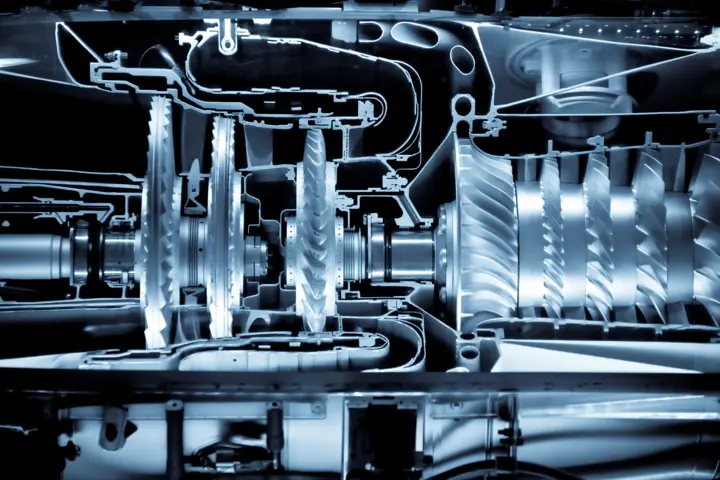

Ground vibration testing (GVT) is a crucial process in aviation R&D and testing, involving both experimental and analytical vibration investigations. This testing is essential for determining the modal characteristics of aircraft structures. By accurately measuring the dynamic response of these structures to various excitation forces, GVT helps identify natural frequencies, mode shapes, and damping properties. This precise data is vital for ensuring the safety, reliability, and performance of aircraft, enabling engineers to validate and optimize structural designs effectively.

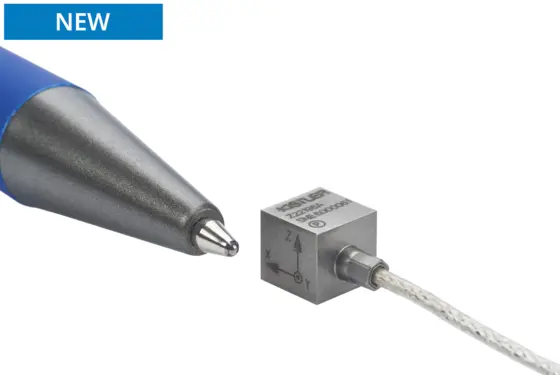

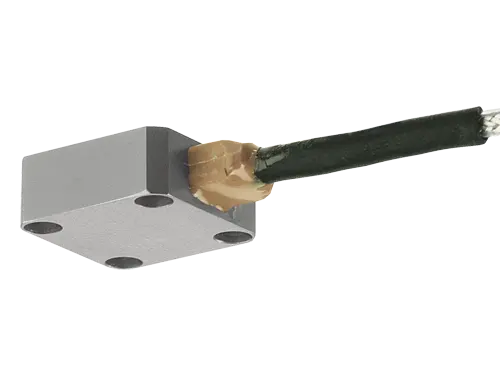

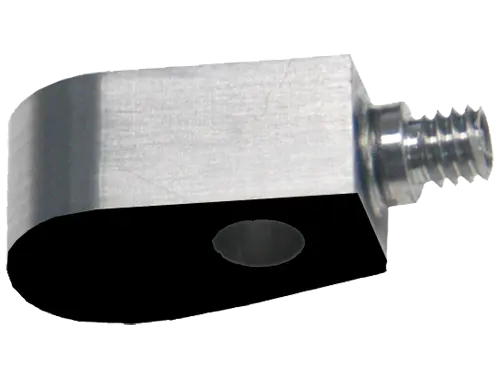

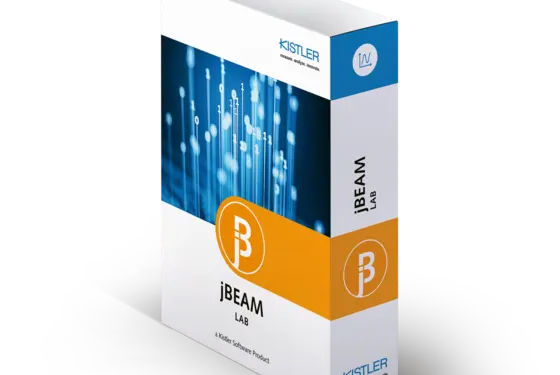

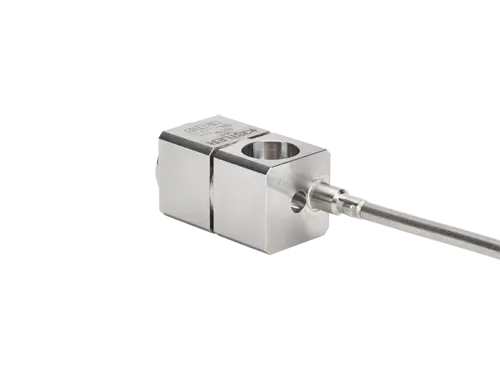

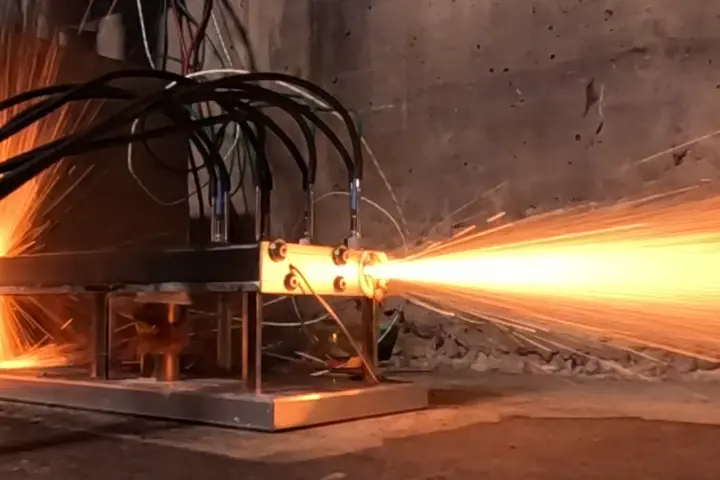

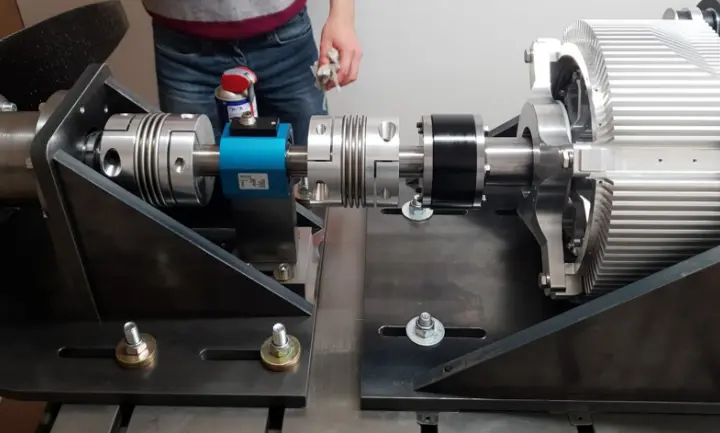

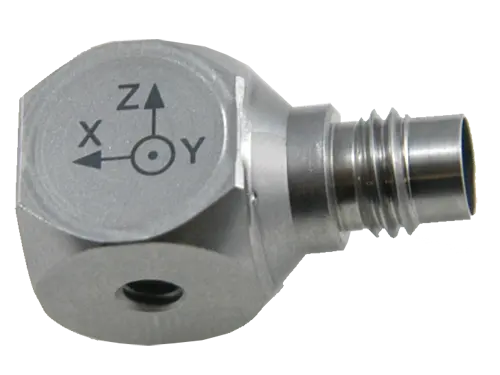

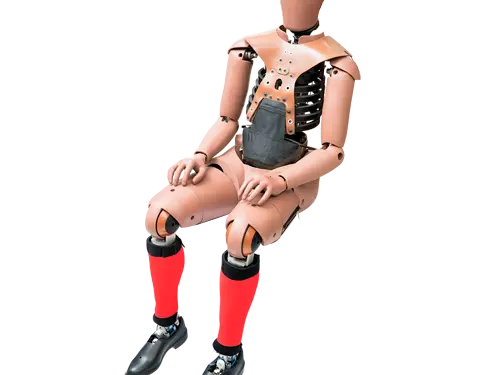

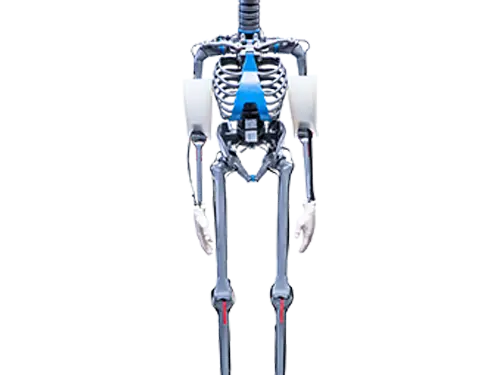

Measurement solutions for aviation applications from Kistler include various top-notch single-axis and triaxial accelerometers but also impulse hammers, signal conditioning systems, data acquisition systems and software.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/Kistler_24.028_b.webp)

![[object Object] MEMS capacitive slim line single axis accelerometer / 8316A](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/Kistler_24.031_8316A.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/Kistler_17.011_5167A81.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/Kistler_17.011_5167A80.webp)

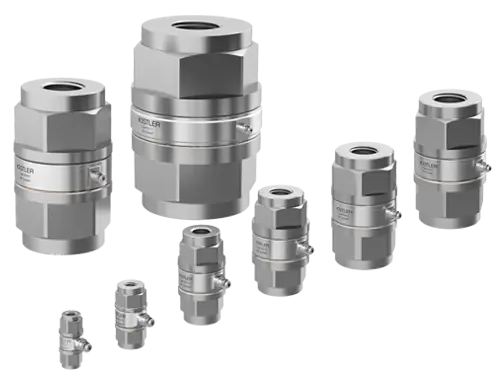

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/6021B_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/4080B_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/934-808_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/931-439_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/932-477_web.webp)