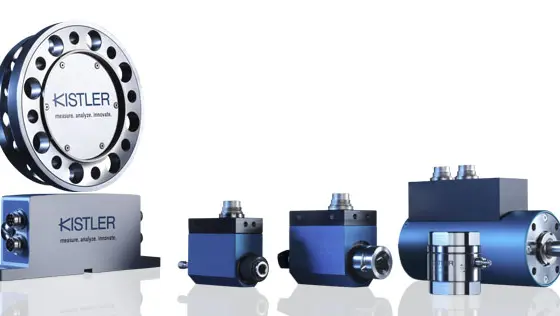

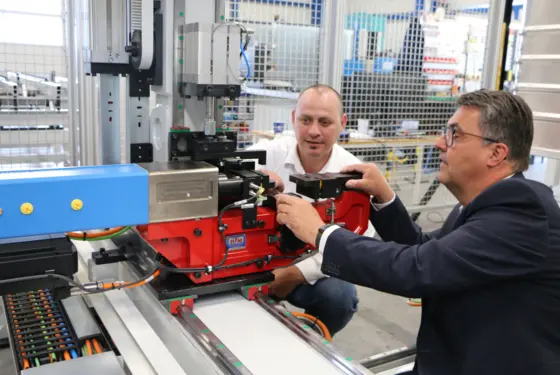

Piezoelectric sensors and process monitoring systems from Kistler make it easy to monitor and control the quality of simple or complex dynamic assembly processes. Both for manual or automated assembly. Faulty parts are identified immediately and filtered out directly during the assembly process to assure quality. Traceability of measurement data is always guaranteed. There is a variety of different sensors measuring force, pressure, or torque to monitor any process step during production.

Quality assurance for assembly – advantages of process monitoring systems from Kistler:

- Suitable for dynamic processes

- Up to 20 measurements per second

- A large number of individually configurable measuring programs

- Excellent flexibility

- Easy to integrate into existing or new production lines

- Traceable documentation of quality relevant production processes

![Force Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-262e.webp)

![Process Monitoring Systems – maXYmos XY Monitors for 100 % Quality in Production, Assembly and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-338e.webp)

![Torque Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-275e.webp)

![Quality Assurance in the Automotive Industry - Zero defects are the basis for lean production [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-189e.webp)

![Quality Assurance in Industrial Production Reproducible Quality with Kistler Force-Displacement Monitoring [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-191e.webp)

![Measurement solutions for automotive test systems [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-240e.webp)