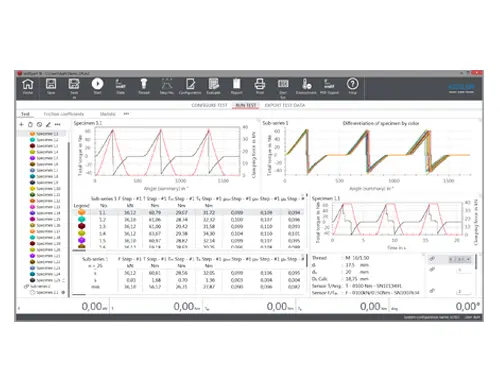

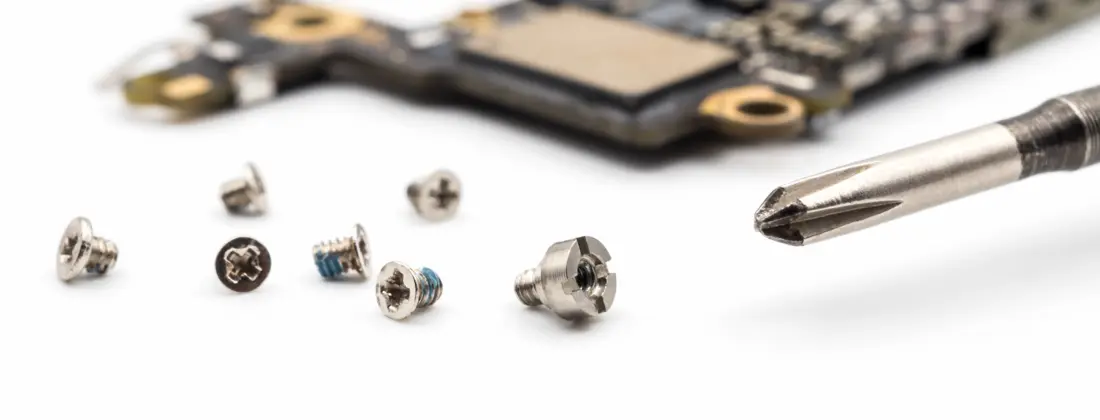

A reliable bolted joint depends on several parameters. The decisive parameter for determining the quality of a bolted joint is the friction coefficient. Familiarity with this coefficient plays a vital role in the design of threaded fasteners and bolted joints in both product development and production in the 3C industry.

It is required to calculate the tightening torque and the resulting preload that holds the parts together. The latter depends on a number of factors that influence the friction coefficient, such as the type of fastener head, strength class, coating, microencapsulation, lubrication, and much more. The friction coefficient must therefore be determined as precisely as possible.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/20170926_Schatz-5413-2777-XE_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/170515_SCHATZ_05_Kistler-logo_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/20170926_Schatz-RS_0009_MKP_web.webp)