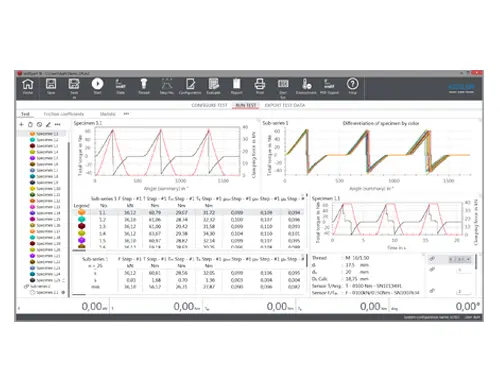

The horizontal ANALYSE system from Kistler facilitates fast and precise testing and analysis of fasteners in conformity with international or customer-specific standards – especially with regard to the determination of coefficients of friction.

To maximize quality and cut costs, fastening technology must be continuously monitored and tested. In virtually every sector of industry, assembly with bolts and screws is one of the most frequently used joining processes in manufacturing. It’s crucially important for bolted joints to function safely and reliably – otherwise, there will be the risk of recalls and additional costs.

![Reliable quality monitoring in production [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-503e.webp)

![Test stands for the analysis of friction coefficients [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-481e.webp)

![The key quality factor is the friction coefficient [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-480e.webp)

![Brochure: Threaded joints [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-641e.webp)

![Zollner Elektronik AG puts its trust in Schatz mobile inspection [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-902e.webp)

![Torque Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-275e.webp)

![Brochure: Process Inspection [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-895e.webp)

![Process Monitoring Systems – maXYmos XY Monitors for 100 % Quality in Production, Assembly and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-338e.webp)

![Product Line for Process Instrumentation and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/300-629e.webp)

![Test stand for torque tools [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-135e_06.25.webp)