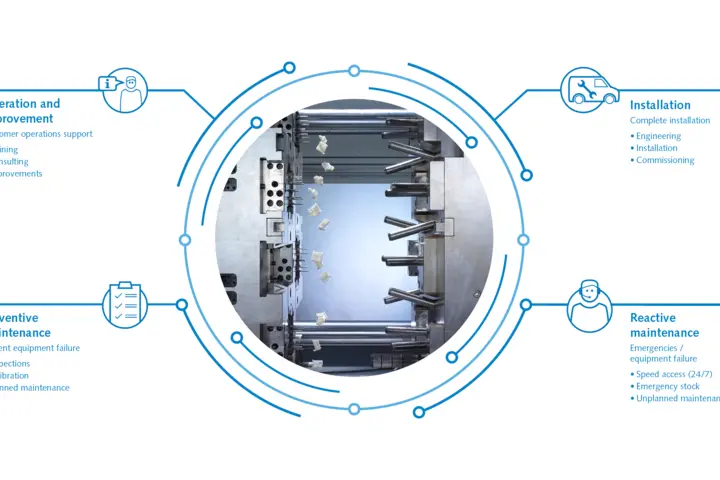

Maintaining high product quality under increasing price pressure is a challenge many injection molders and mold makers face nowadays. At the same time, requirements on traceability of the molded parts become higher. To ensure an efficient process along the development and production of a new plastic part, we offer a broad service portfolio to accompany our customers in different phases. We help you to reduce process risks, to lower costs for commissioning and to achieve long-term stable product quality. Benefit from our in-depth application knowledge and explore the Kistler Original Service offerings for each lifecycle phase!

Services for injection molding

Comprehensive services for plastic injection molding: expert support at every stage of the lifecycle

Installation

Mold design has an important influence on plastics processing and on product quality. To reduce risks in the design phase, Kistler offers a simulation service to simulate the planned injection molding process. As a result, we can consult you on the best sensor placement within the mold and deliver a recommendation on the process parameters. In addition, the service Mold Validation 1 serves to inspect the mounting bores of the molds and to correctly commission all sensors. The provided report documents correct mold installation and operational readiness of the measurement equipment. This streamlines the setup and facilitates the collaboration between mold maker and injection molder.

- Risk simulation

- Mold Validation 1

Reactive Maintenance

In the rare case of equipment failure the Kistler Original Service is there to support you in a fast and efficient way. Our emergency stock ensures that you get the right spare parts in a timely manner in order to support you exactly when you need it. We help you as well with the availability of your equipment: our rental devices enable continuous production during repair times and increase your overall equipment efficiency.

- Emergency stock

- Rental service during repair

Preventive Maintenance

Regular calibrations and inspections ensure a high level of process reliability and long-term protection for your equipment. This is based on precise measurement solutions which guarantee error-free production. Periodic updates of our proprietary software tools such as Stasa QC, ComoNeo, and AkvisIO IME keep user experience and availability high and deliver new features.

- On-site calibration

- Planned on-site inspections

- Software and firmware updates

Operation & Improvement

Kistler built up its injection molding know-how over several decades and employs process specialists all over the world. Through our ISO21001 certified Kistler Academy we impart this knowledge: for example with courses on composites production, sensor basics or process optimization with ComoNeo. – Commissioning of measurement technology is optimally complemented by the Mold Validation 2 service to check the plausibility and optimal setup of process parameters including the recording of a reference curve and a validation certificate.

- Trainings in Kistler Academy

- Mold Validation 2

![Customer service solution, all about the plastic injection molding [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/962-011e.webp)