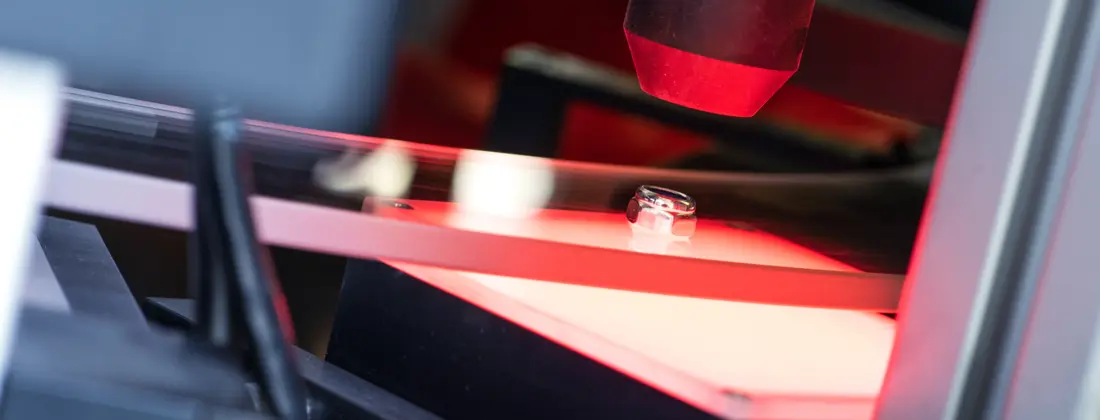

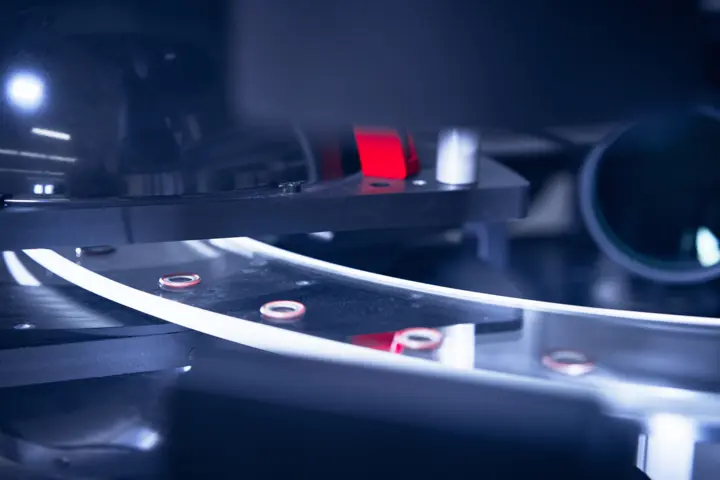

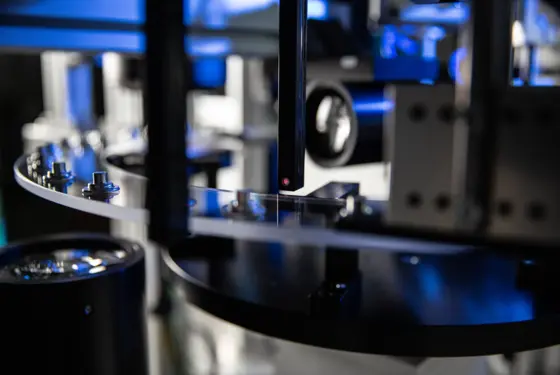

The KVC 621 is a universal, autonomous video measurement system for 100% inspection of continuously produced parts. In this system, the integrated control and image processing components focus on high, individually adjustable processing speeds for complex assignments with transmitted and reflected light.

The KVC 621 test system for continuous material is available in various sizes including an extra-compact version (for confined spaces) and a version with extended installation space (e.g. to accommodate additional cameras or to integrate a marking laser).

Individual testing and sorting functions

- Conventional dimensional checks

- Complete contour tracing for errors that occur sporadically

- Detection of surface defects

- Individually adjustable error response

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Video_Preview_96x64/kvc-621-test-systems-for-continuous-materials-in-punching-processes-test-automation-by-Kistler-32284j.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/cover-picture-961-502-download-30457.webp)

![Vision Inspection - Automated test systems for mass-produced and series parts [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-174e.webp)

![Smart stamping: inline process control for stamping [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-824e.webp)

![New AI-supported possibilities in injection molding production with fully automated optical quality assurance [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-884e.webp)