Studies show that around eight percent of all calibrated testing and measuring devices are found to have deviations that require adjustment or repair. Undetected measurement errors lead to inaccurate results, increased reject rates and production losses. The management of recurring calibration intervals is therefore an important factor in differentiating oneself from the competition and ensuring consistently high quality in development and production.

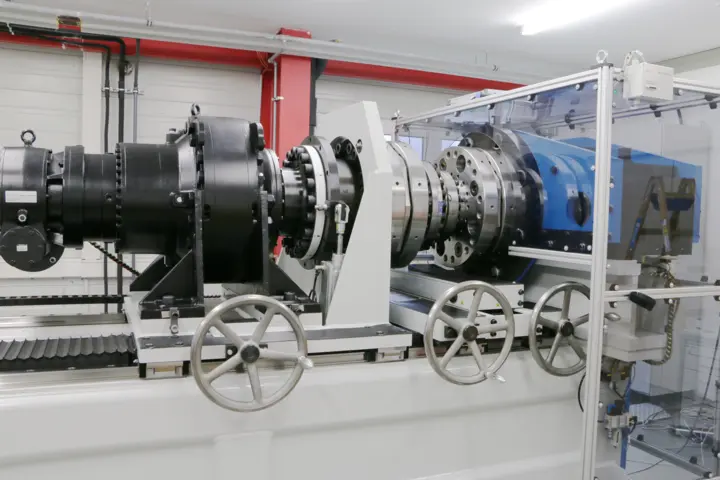

Torque calibration is an essential part of quality assurance in numerous industries, from the automotive and aerospace sectors to medical technology. Kistler offers accredited torque calibrations in accordance with ISO 17025 and guarantees minimum measurement uncertainties of up to 0.01 percent. The very wide measuring range from 4 mN·m to 100,000 N·m is covered by five ultra-modern calibration systems. Thanks to the unique calibration system and particularly in the upper measuring range of 5,000 to 100,000 N·m, Kistler can also offer service calibrations for third-party products – providing customers with additional high-quality calibration services from a single source.

![Calibration service: accredited torque calibration from Kistler now available up to 100,000 N·m [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-319e.webp)

![Calibration services [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-077e.webp)

![Calibration interval guide [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-472e.webp)