温特图尔,2025年9月—奇石乐凭借其独特的 NCFQ 2166A 伺服压机系统 ¹,实现了线性直驱的高动态特性与压电传感器技术精准优势的突破性融合。作为动态测量与装配技术领域的专家,奇石乐结合 LinMot² 的成熟驱动技术,并融入压电传感器对其高速伺服压机系统进行了性能优化。这款创新的交钥匙系统可选配加速度补偿功能,精准填补了医疗、电子产品制造、半导体生产及汽车工业等对质量与生产速度均有严苛要求的市场领域的空白。

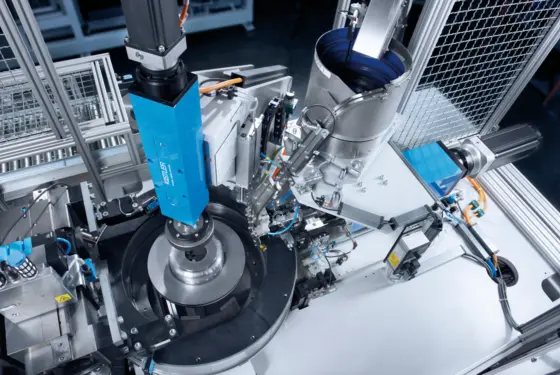

在低力值(最高 500N)的高动态应用场景中(如自动注射器终组装), 新型 NCFQ 高速伺服压机系统优势显著。该伺服压机系统因配备传感器,在电子行业的继电器测试或触觉检测中亦能发挥关键作用。该系统的压机模块采用线性电机与磁基技术,垂直安装时通过磁基弹簧实现重力补偿,最高可实现50 m/s²加速度与5 m/s运行速度。奇石乐通过集成压电式力传感器、压电式加速度传感器、ICAM-B 工业电荷放大器及 maXYmos NC 过程监控系统,使该伺服压机系统能确保高速生产过程的数据透明、过程可靠且具备过程控制能力。

![High-speed assembly and joining technology meets precise force measurement [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-331e.webp)

![High-speed joining systems NCFQ, Type 2166A [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/003-727e.webp)