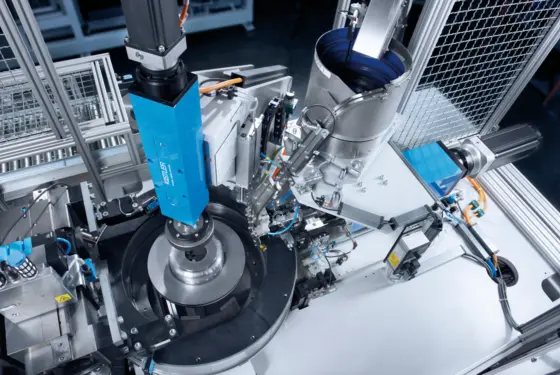

Winterthur, September 2025 – With its unique NCFQ 2166A joining1 Kistler combines the high dynamics of linear direct drives with the precision of piezoelectric sensor technology. As experts in measurement and joining technology, they use the proven drive technology from LinMot2 and enhance it with piezoelectric sensors. The innovative turnkey systems come with optional acceleration compensation. They fill a gap in markets where quality and high production speeds are particularly important – such as the manufacturing of medical and electronic products, semiconductors, or in the automotive industry.

Especially highly dynamic applications with low forces of up to 500 N – like the production of autoinjectors and insulin pens – benefit from the new NCFQ high-speed joining system. Being equipped with sensors, the joining system also shows its strengths in the electronics industry in relay or haptic tests. The magnet-based technology of the joining module featuring a linear motor accelerates at up to 50 m/s² and reaches speeds of up to 5 m/s. In addition to the linear motor, the module has a magnetic spring for weight compensation in vertical installation positions. Kistler complements the system with piezoelectric force and acceleration sensors, the ICAM-B industrial charge amplifier, and the maXYmos NC process monitoring system, which ensures data transparency, process reliability, and process control.

![High-speed assembly and joining technology meets precise force measurement [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-331e.webp)