While discussions of the energy transition often focus on wind and solar power, hydropower is also a significant player on the global stage. In 2024, hydropower contributed around 4,400 terawatt hours (TWh) to worldwide electricity generation with a 14 percent share of the total, placing it third behind coal and natural gas. What’s more, estimates suggest hydropower’s global potential could exceed 16,000 TWh annually – even considering ecological factors such as the impact of dams on landscapes and ecosystems. Hydropower also offers flexibility and huge energy storage capacity which are critical assets for balancing a grid with an increasing share of renewables.

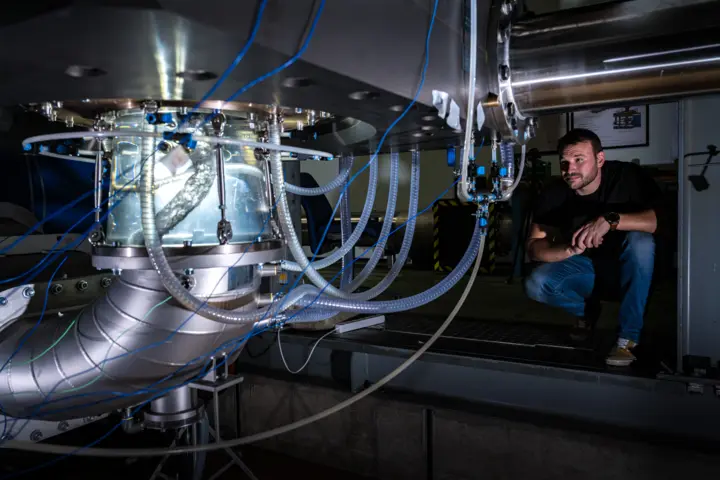

Electricity is generated in a hydropower plant by turbines that convert the potential energy of falling and the kinetic energy of flowing water into electrical energy. There are several types of hydraulic turbine design, each with their own specific strengths: the most common types include pump turbines, Francis, and Kaplan, named for their respective inventors. Given the high investment costs and because of the individual conditions at each hydropower plant, planned turbines must undergo intensive model acceptance testing before installation. Turbine test stands utilize accurately scaled models of hydraulic water passages to capture parameters such as pressure pulsations, cavitation, efficiency and output power

![Optimizing hydropower to support the energy transition [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-975e.webp)