Loose part monitoring

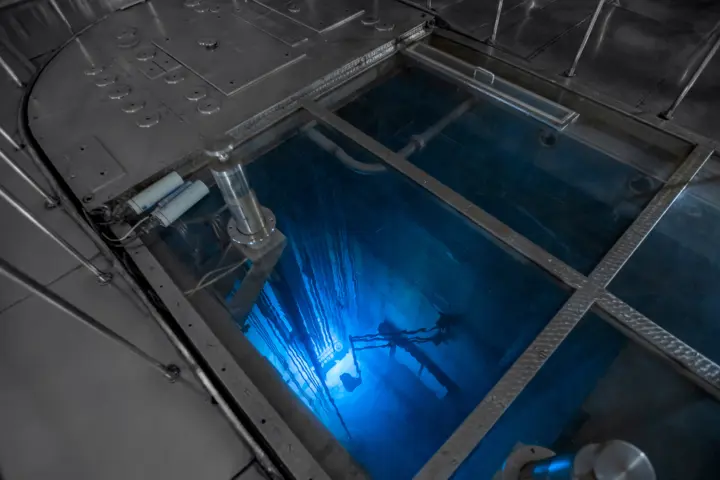

Nuclear power plants are complex structures with thousands of small components such as fixtures, valves and screws. Loose parts resulting from wear and fatigue or maintenance errors can cause critical safety and performance issues. Early detection of loose parts helps to avoid or mitigate damage and malfunction of primary system components.

A Loose Part Monitoring System (LPMS) typically consists of a set of accelerometers placed in critical spots of the monitored system (e.g. reactor vessels, steam generators or coolant pumps) and according cabling and electronics for data processing. Kistler is able to deliver complete measuring chains for LPMS based on specific customer requirements.