Stay up to date

Intertraffic 2026: Kistler showcases digital Structural Health Monitoring solution for bridges

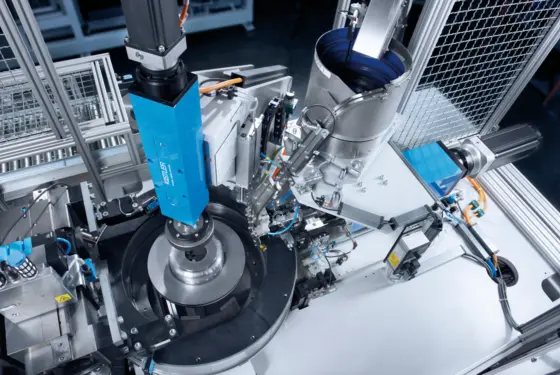

Real-time insights and scalable automation for cutting-edge medical device production

Success stories

ARIS Perseus achieves proof of concept for RDRE with Kistler measurement technology

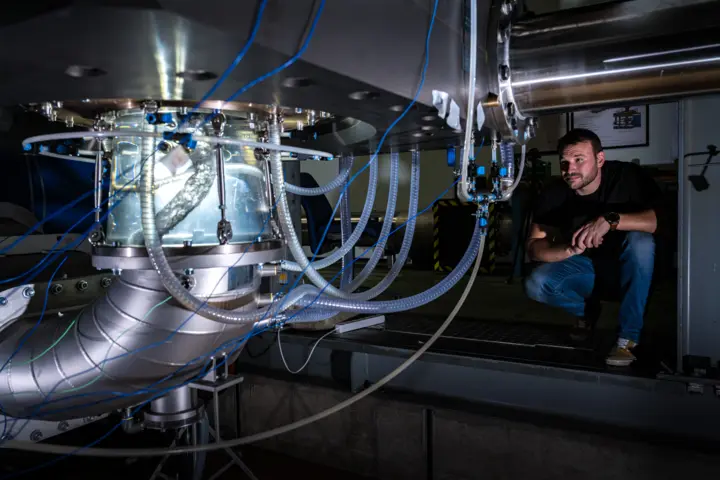

EPFL PTMH opts for Kistler pressure sensors to conduct R&D model tests on hydraulic turbines

New products and software releases

Discover our applications and services

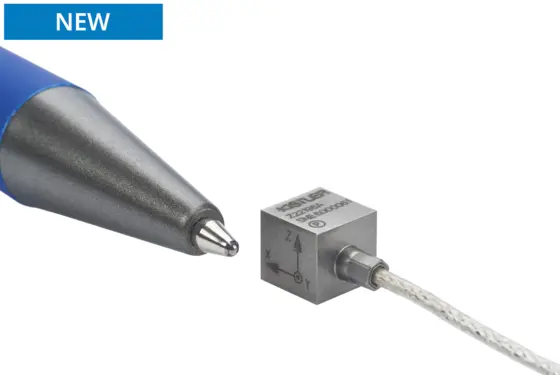

Piezoelectric measurement technology from Kistler - complete systems from sensor to cloud

As a global leader in dynamic measurement technology for measuring pressure, force, torque and acceleration, we support our customers in industry and science to improve their products and make their manufacturing processes more efficient. The piezoelectric sensor is at the heart of every measurement system from Kistler and, based on piezoelectric technology, the most important element of our measurement technology.

To offer you sensors, measurement systems and services that are exactly tailored to your needs, we fully focus upon the complex current and future challenges in the areas of automobile development, industrial automation and in fields related to extreme environments. We are a dedicated industry insider and by offering our measurement technology, make important contributions towards the further development of current megatrends, including electrified drive technology, autonomous driving, emission reduction and Industry 4.0. Built upon more than 60 years of deep application knowledge, our comprehensive product portfolio covers all applications and services in piezoelectric measurement technology.