The Piezo Tool System app facilitates research in metal cutting and machining applications: this new solution from Kistler was successfully tested at Chalmers University of Technology.

Successful advances in the development of machining methods, cutting tools and processes depend on two factors: state-of-the-art instruments and technology on the one hand, and highly trained researchers on the other. Both these requirements are excellently met at Chalmers University of Technology in Gothenburg, one of Sweden’s leading research centers. This institution’s origins date back to 1829, when Swedish merchant William Chalmers left a legacy to establish a ‘technical school’ that has since become one of Europe’s most respected universities of technology, with over 11,000 students and almost 3,000 teaching and research staff at its two Gothenburg campuses. Chalmers is home to many R&D facilities including the International Grinding Centre (IGC), where academic research and industry collaborate on developing new technologies and skills to optimize grinding applications.

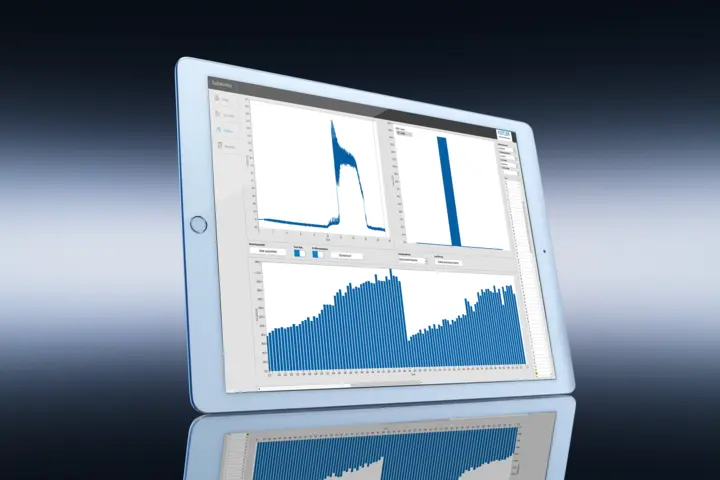

Peter Krajnik is the founder of the IGC, Professor of Manufacturing Technology at Chalmers University of Technology, and a Member of the International Academy for Production Engineering (CIRP). Krajnik and his team play a key part in the IGC’s work by developing and optimizing the automation of R&D tools and processes. He says: “High-quality research is inconceivable without high-level skills as well as high-caliber research tools. Research into metal cutting tools requires particularly extensive testing, analysis and reporting. Large numbers of test cycles are essential to achieve a high degree of consistency, and to enable publications of high quality.”

![Chalmers University of Technology advances metal cutting research with the PTS app from Kistler [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-962e.webp)