KiBox2 E-Powertrain Analysis is an innovative complete solution that serves as an indispensable tool for research and development in the field of electric and hybrid drives. The power analyzer was developed to support every phase of the development process – from integration and calibration all the way to optimization and verification. It can take measurements at individual drive components, such as power electronics, inverters, e-motors, and resolvers, and also measure component assemblies. Direct or alternating current, high- or low-voltage measurement, or the analysis of energy management systems – KiBox2 E-Powertrain Analysis is designed for every challenge. The scalable system with up to 64 measuring channels and powerful processing functions records the necessary measurement signals across the entire powertrain. KiBox2 E-Powertrain Analysis differs fundamentally from standard DAQ systems because the measured signals are immediately processed via dedicated software solutions, meaning that detailed visualization and analysis of application-specific e-machine data occur in real time. At the same time, the system can also measure and process specific measurement currents from current transducers, which are primarily used in high-voltage applications, as well as signals from standard current clamps.

Power analyzer for the development and testing of electric and hybrid powertrains

Winterthur, November 2025 – KiBox2 E-Powertrain Analysis is the comprehensive solution for the development, testing, benchmarking and validation of complete electric, hybrid, and fuel-cell drives – both on test stands and in vehicles. Kistler designed the new hardware and software components for simple integration into existing KiBox2 systems. The modular and scalable solution can be configured for virtually every conceivable measurement scenario and area of application – on land, in the water, or in the air. KiBox2 E-Powertrain Analysis is equipped for the challenges encountered in the field of electric and hybrid drives: it is characterized by its ability to process strong currents, high voltages, and rapid switching frequencies without issue while also remaining immune to interference. Thanks to its compact and robust design, it can be installed directly in test vehicles. It is ideal for the comprehensive analysis not only of complete electric and hybrid powertrains, but also of individual drive components and assemblies. It offers real-time measurement, visualization, and recording of all relative drive parameters with advanced cycle detection and ultra-fast calculation windows that allow for highly dynamic and precise testing procedures.

Testing electric and hybrid drives with groundbreaking technology

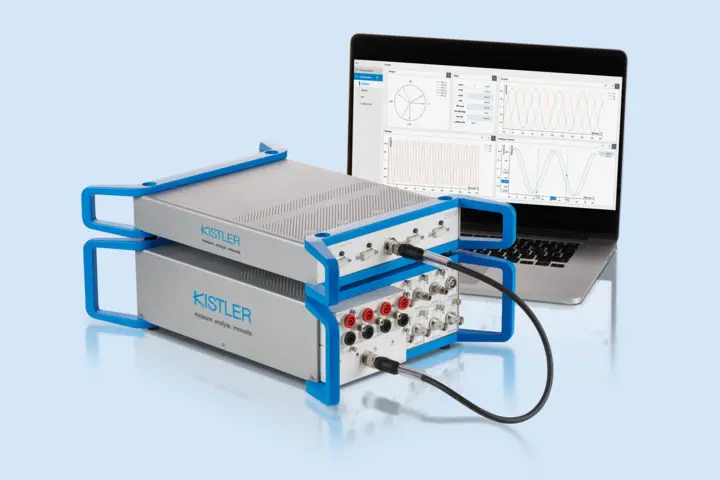

For data acquisition and power analysis of electric powertrains, KiBox2 E-Powertrain Analysis is comprised of three compact components:

- KiBox2 16-channel measuring unit: A compact, mobile power analyzer for real-time measurement, calculation, and visualization with rapid processing of 2.5 MS/s per channel.

- HVAQ 4-channel high-voltage module: An electrically isolated voltage module with a measuring range of up to ±1000 Vrms / ±1500 Vpeak. Safety level 1000V CAT II / 600V CAT III.

- HCAQ 4-channel high-current module: Measuring ranges of up to 2000 A can be realized thanks to the Current Conditioner Box, which allows for the use of external zero-flux current transducers.

Versatile, precise, robust, compatible, and effective

The overall system is easy to install and integrate into test stand automation systems – and, thanks to its compact and robust design, it is also suitable for in-vehicle test scenarios. On-track vehicle testing places unique requirements on hardware. KiBox2 E-Powertrain Analysis can be installed on the inside of the vehicle, can withstand strong vibrations, and can be connected to the vehicle’s power supply. At its core, KiBox2 has a powerful electrical power analyzer that is tailored to the specific requirements of electric powertrains. It allows for the precise measurement and calculation of electrical power flows and losses with high-resolution data storage for detailed offline analysis.

KiBox2 can be set up quickly and features an intuitive user interface. The advanced signal conditioning simplifies the analysis of electric power, making it possible to quickly identify losses. The intelligent algorithm ensures precise real-time cycle detection and can be flexibly configured up to one-quarter of an electrical cycle. All data is saved in an ASAM-compatible format (.mdf). For custom workflow integration, a corresponding converter can be used to output alternative data formats.

A power analyzer for cross-platform power analysis

Power analysis can be carried out simultaneously on electric powertrains and powertrains that use combustion technologies, such as range extenders, with a single system. Synchronized data acquisition and calculation of crank-angle and time-based measurands allows for combined energy flow analysis in both domains. Moreover, mechanical torque systems can be directly connected to KiBox2 via analog or digital inputs. By including physical parameters like speed and torque, KiBox2 is expanding the range of applications to include mechanical power analysis.

Flexible power measurement – regardless of how the industry develops

Vehicle efficiency has been a key issue in the automotive industry long before the rise of alternative drive technologies. With the ability to combine measurements and analysis of electric and combustion drives and, moreover, to record mechanical signals from torque systems, Kistler is providing research and development teams with a system that leaves nothing to be desired. For the processing of measurement data, the newly developed “E-Powertrain” application module has been added to the proven “Cockpit” software solution. Kistler’s jBEAM Powertrain software for the further processing of data allows the company to cover the entire spectrum and offer one of the most comprehensive overall solutions on the market.