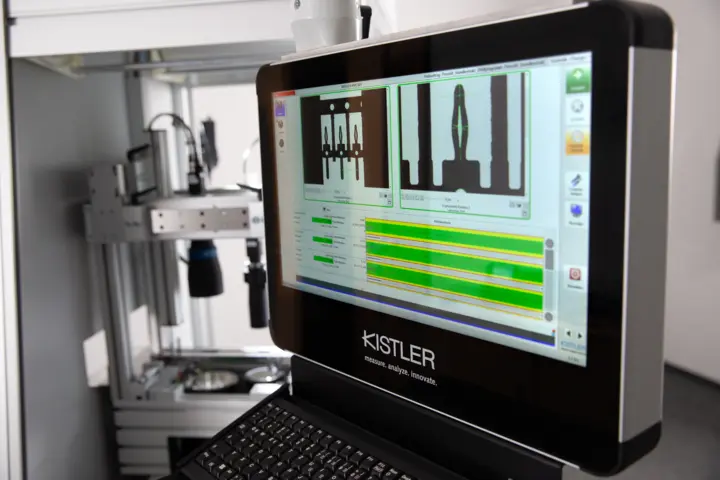

There are many production environments where every square centimeter is crucial: stamped part manufacturers are among those who have to utilize the space available for their production processes as efficiently as possible. Knowing this, Kistler has developed the compact KVC 621 SE automated optical testing system specifically for quality control in mass production.

This new system handles all testing jobs within a housing that is only 600 millimeters wide and 900 millimeters deep – with the added advantage of fast and straightforward installation. Unlike pneumatic solutions, the KVC 621 SE is not reliant on compressed air thanks to its fully electromechanical drive. A digital feedthrough loop also enables users to save valuable space by positioning the automated testing system closer to the stamping press. The KVC 621 SE comes equipped as standard with up to three integrated camera stations and a sensitive touchscreen so the system can be delivered and commissioned quickly – within only four to six weeks.

![KVC 621 SE: the new compact testing solution for mass-produced stamped parts [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-272e.webp)