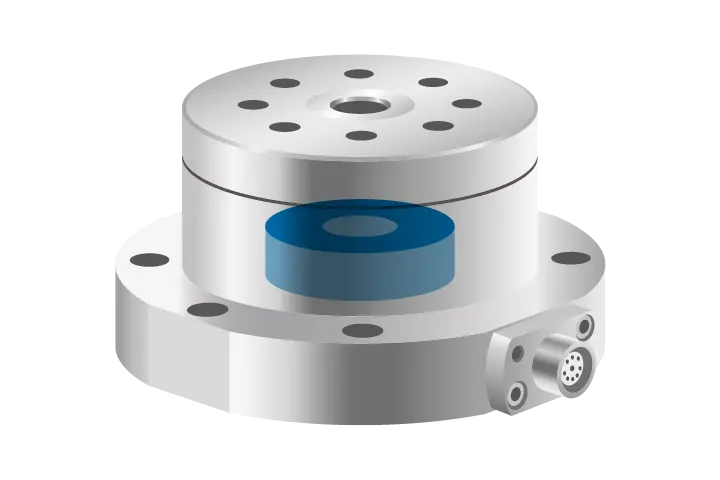

For universal use: the handy table-mounted 9257B multicomponent dynamometer offers a measuring range of up to 10 kN – making it ideal for many applications.

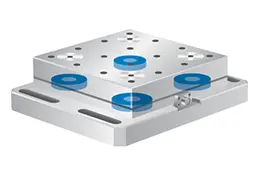

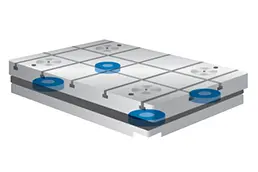

Robust: the 9255C is one of the largest dynamometers in Kistler's range – and with its robust platform, it is optimized for heavy machining. It can measure cutting forces of up to 60 kN. This dynamometer also gives you the option of preloading above the center of the four sensors to make optimal use of the natural frequency.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/dynamometer-9109aa_46962.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/dynamometer-91x9aa_46960.webp)

![Cutting force measurements in research and development [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-002e.webp)

![Analyzing highly dynamic forces [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-165e.webp)

![Cutting force measurement leads to superior tooling concept [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-074e.webp)

![Evaluation of cooling lubricants under operating conditions [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-671e.webp)

![More robust, with higher precision and longer lifetimes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-302e.webp)