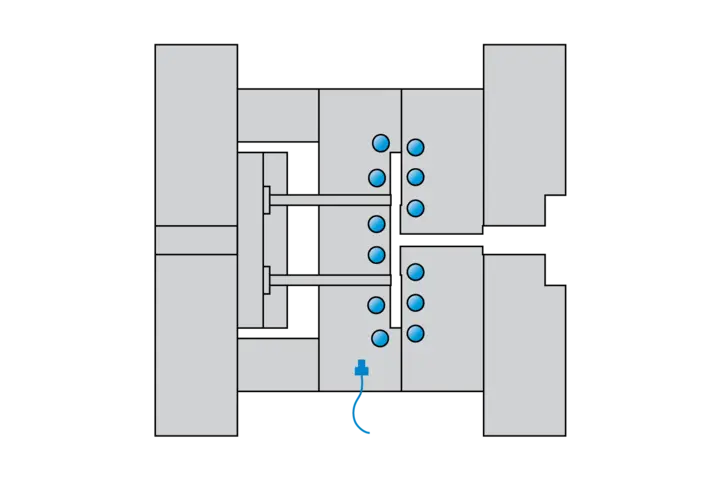

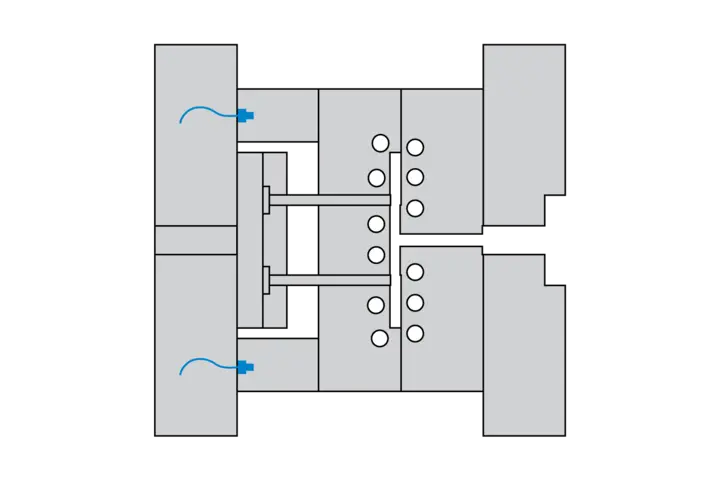

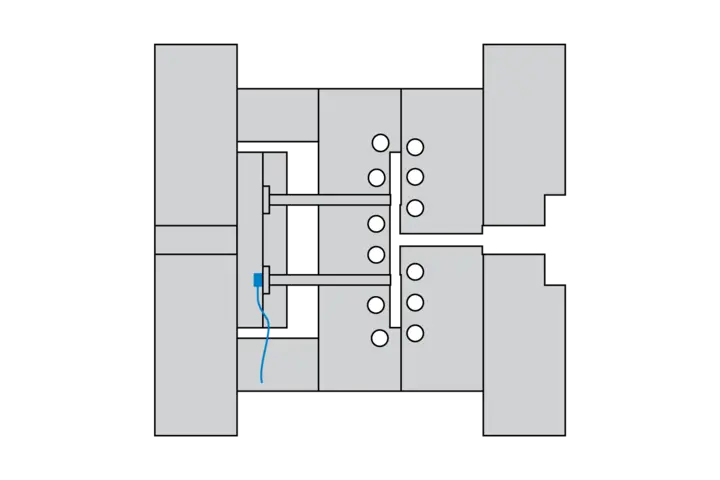

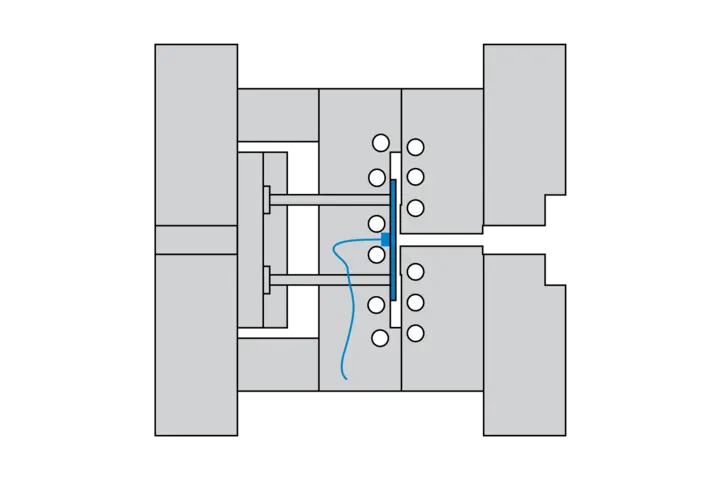

Alongside pressure, temperature is one of the most important process values in the injection molding process. To ensure controlled and reproducible dissipation of the heat from the mold, injection molds are kept within a narrow temperature range: this is achieved by a temperature control medium (usually water) and a temperature control device. Different temperatures may also be necessary in one tool.

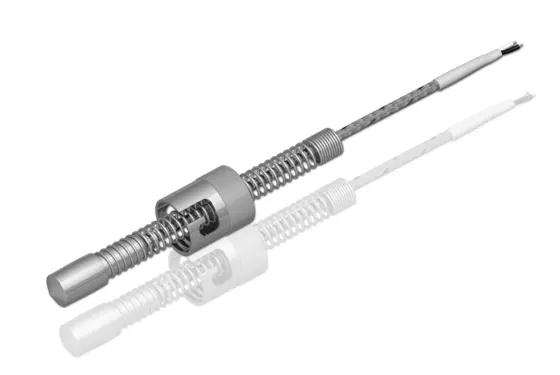

A maintenance intervention is indicated if the flow of the medium through the temperature control channels in the mold is impeded and the heat transfer to the tool wall is restricted (by deposits, for example). A simple and cost-effective temperature sensor placed in the mold enables prompt detection of malfunctions in this complex system.

![Sensors and systems for Quality monitoring and process control in injection molding [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-112e.webp)

![Sensors for Punching, Forming and Automation Systems [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-173e.webp)