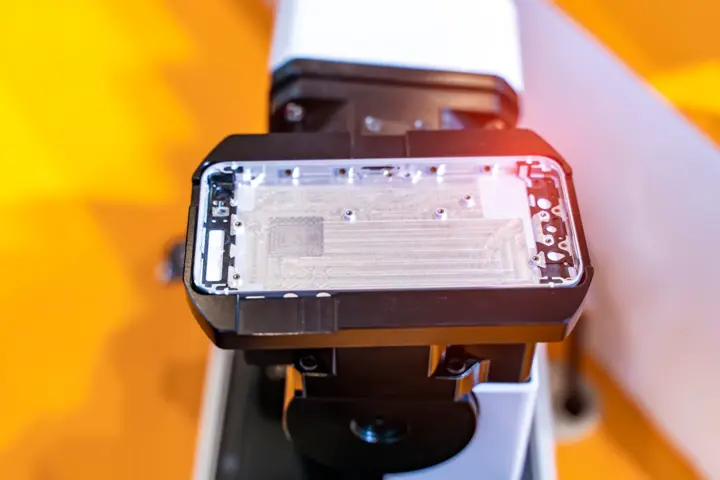

Reliable machining is a prerequisite for achieving functionally and visually flawless products. But large-scale precision machining of thin-walled, lightweight components – such as housings for smartphones and tablets etc., scratch-resistant display glass used for high-quality touch screens, glass backplates, phone backboards etc. – is becoming more and more critical in the 3C electronics industries:

The rising demand for 3C electronic products poses manifold challenges to suppliers in the precision machining industries. This is due to new materials used, as well as to higher requirements for the surface quality put forward by manufacturers. An aggravating challenge is that the development of stable manufacturing processes and tool designs is difficult due to the complexity of the machining process compared to other manufacturing processes. One of the reasons for this is that in mass production, tool wear is a key factor for the quality and cost of the goods produced.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/935-900.webp)

![Cutting force measurement leads to superior tooling concept [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-074e.webp)

![Evaluation of cooling lubricants under operating conditions [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-671e.webp)

![Cutting force measurement leads to sophisticated machining processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-057e.webp)

![Analyzing highly dynamic forces [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-165e.webp)

![More robust, with higher precision and longer lifetimes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-302e.webp)

![A turn for the better [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-393e.webp)

![Cutting force measurements in research and development [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-002e.webp)

![Force Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-262e.webp)

![Charge amplifiers [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-907e.webp)

![Test & Measurement acceleration, acoustic emission and dynamic force [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/900-380e.webp)

![New service for machining: milling optimization [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-258e.webp)