Amsterdam, January 2026 – At Intertraffic Amsterdam (March 10–13), Kistler will present its latest innovation in infrastructure monitoring: its first fully digital Structural Health Monitoring (SHM) system for bridges. This next-generation solution marks a significant leap forward in how operators monitor, maintain, and protect critical assets – combining real-time structural insights with data-driven decision-making to ensure safety and longevity. Visitors can find free trade fair tickets on the Kistler website.

Across the globe, aging bridge infrastructure faces unprecedented challenges. Increasing traffic volumes and heavier vehicle loads accelerate fatigue and structural degradation, yet maintenance budgets remain tight. At the same time, damage often develops long before it becomes visible, making early detection essential to avoid costly repairs or dangerous failures.

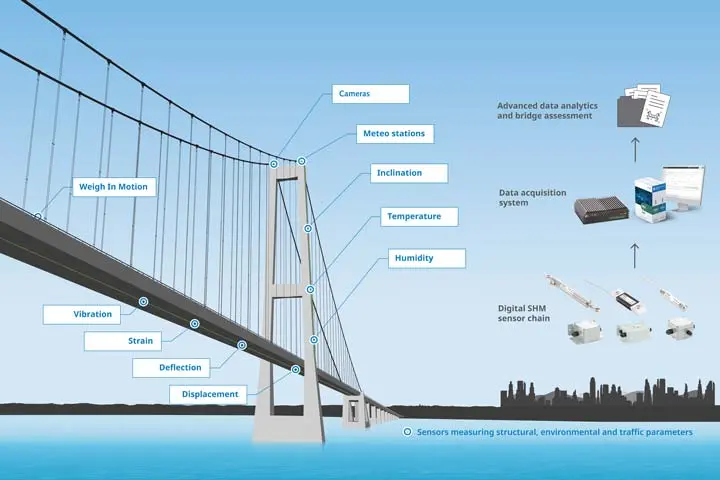

The new fully digital SHM solution from Kistler for bridge monitoring addresses these challenges head-on. The measurement system delivers actionable insights and an objective view of how bridges behave under actual operating conditions. This enables infrastructure operators to detect damage at an early stage, to prioritize maintenance effectively, and extend service life.

![Intertraffic 2026: Kistler showcases digital Structural Health Monitoring solution for bridges [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-358e-01.26.webp)