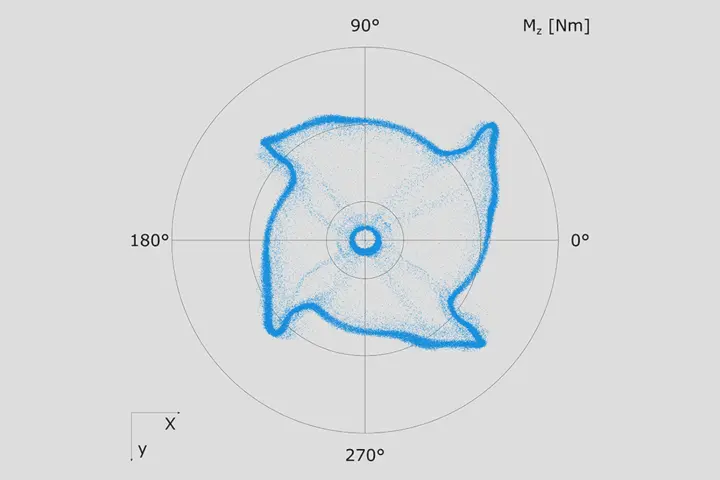

Extensive measurements of individual cutting-edge engagements

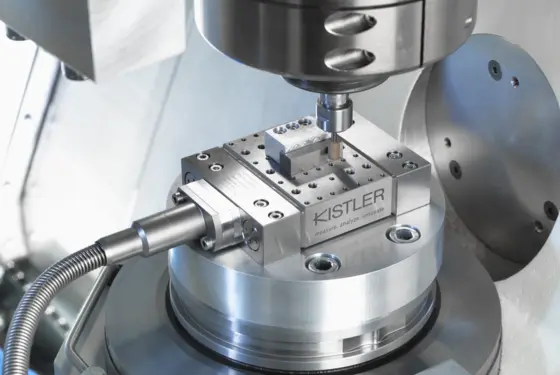

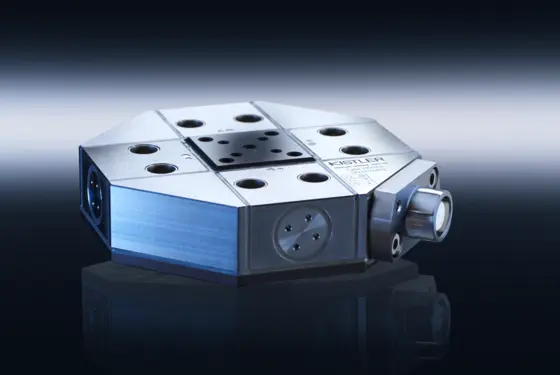

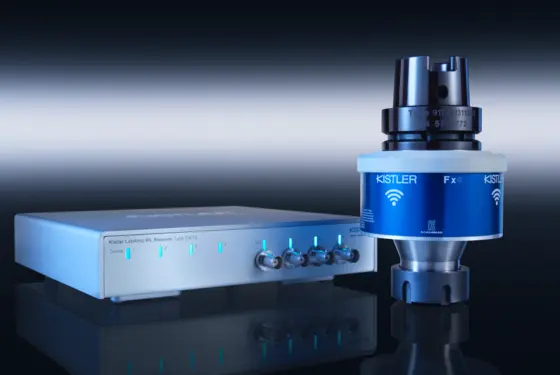

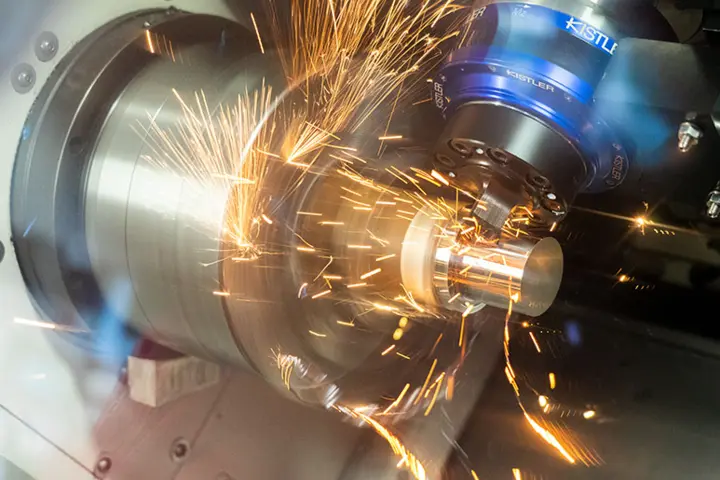

Piezoelectric cutting force measurement technology can resolve individual cutting-edge engagements. The sensors measure forces with high precision – even for highly dynamic processes and at maximum speed.

![Cutting force measurements in research and development [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-002e.webp)

![The right technology to monitor machining processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-437e.webp)

![Cutting force measurement leads to superior tooling concept [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-074e.webp)

![Evaluation of cooling lubricants under operating conditions [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-671e.webp)

![Cutting force measurement leads to sophisticated machining processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-057e.webp)

![Analyzing highly dynamic forces [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-165e.webp)

![More robust, with higher precision and longer lifetimes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-302e.webp)

![Tapping into success [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-474e.webp)

![A turn for the better [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-393e.webp)