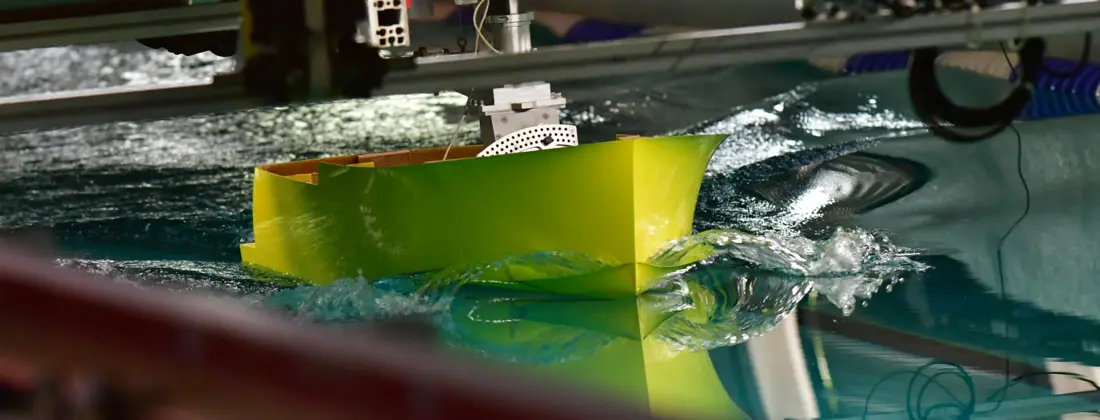

Towing tanks play a key part in many different tests on ship models. Examples include resistance and propulsion tests that are performed with both towed and self-propelled models. Towing tanks are also used in scaled-down tests to determine a vessel's maneuvering behavior. Kistler supports researchers with multi-component force sensors and dynamometers capable of high measuring ranges as well as high and low frequencies – enabling also accurate quasi-static measurements. In some cases, acceleration is measured at the same time as force and moment, using accelerometers.

To extend their application scope, towing tanks can be fitted with additional equipment such as a planar motion mechanism (PMM) or a computerized planar motion carriage (CPMC). These devices measure the hydrodynamic forces and moments acting on ships or submerged objects due to the influence of oblique inflow and enforced motions. Another possibility is to equip the towing tank with a wave generator to carry out seakeeping tests.

![Solutions for hydrodynamic testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-258e.webp)