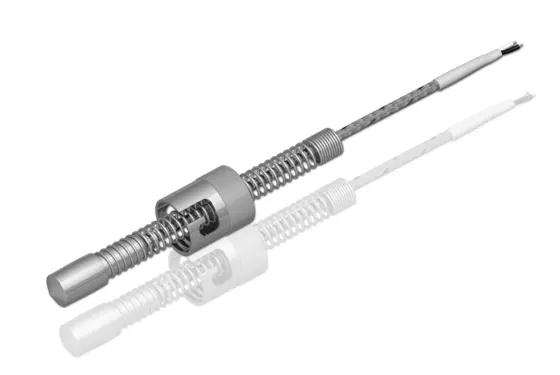

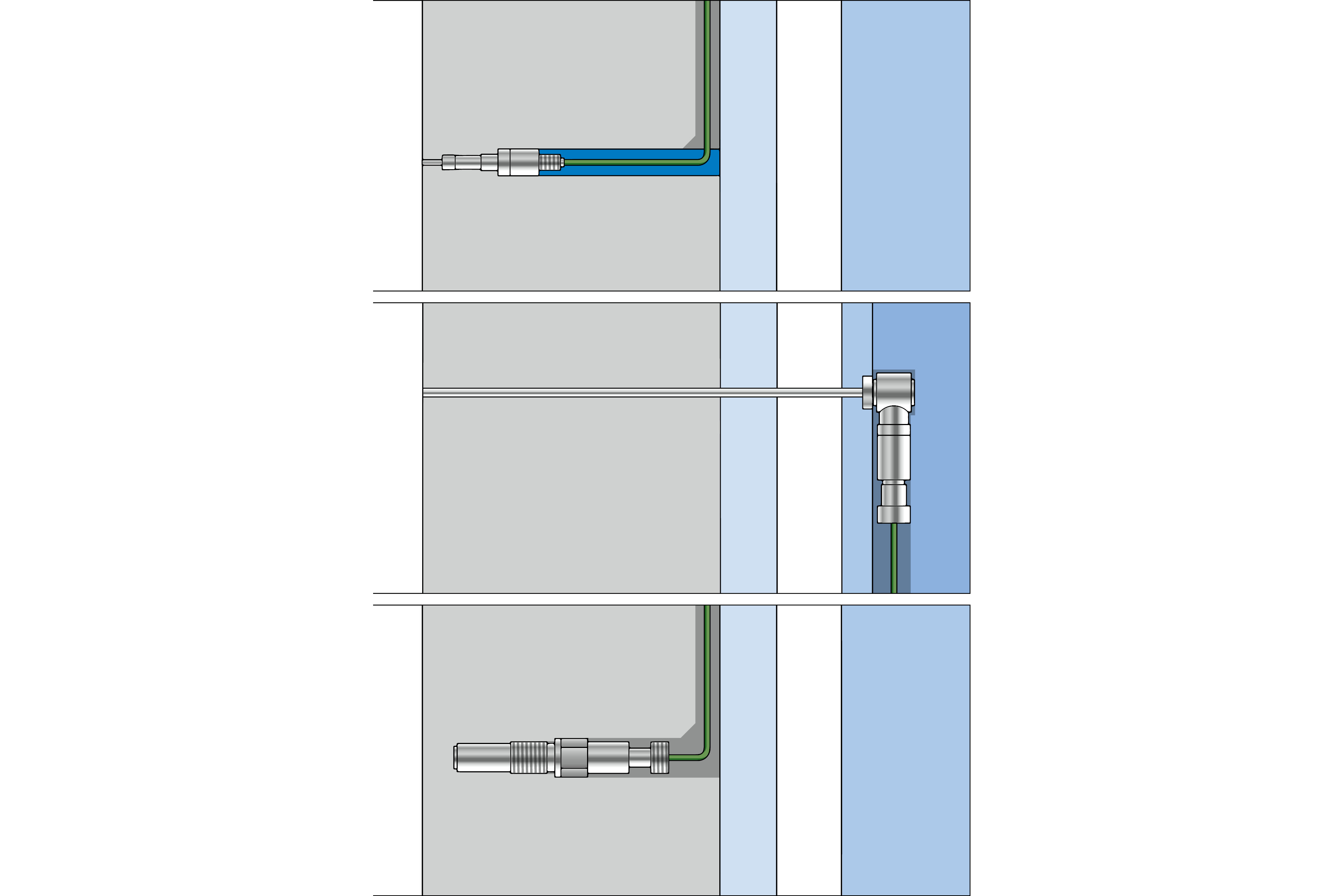

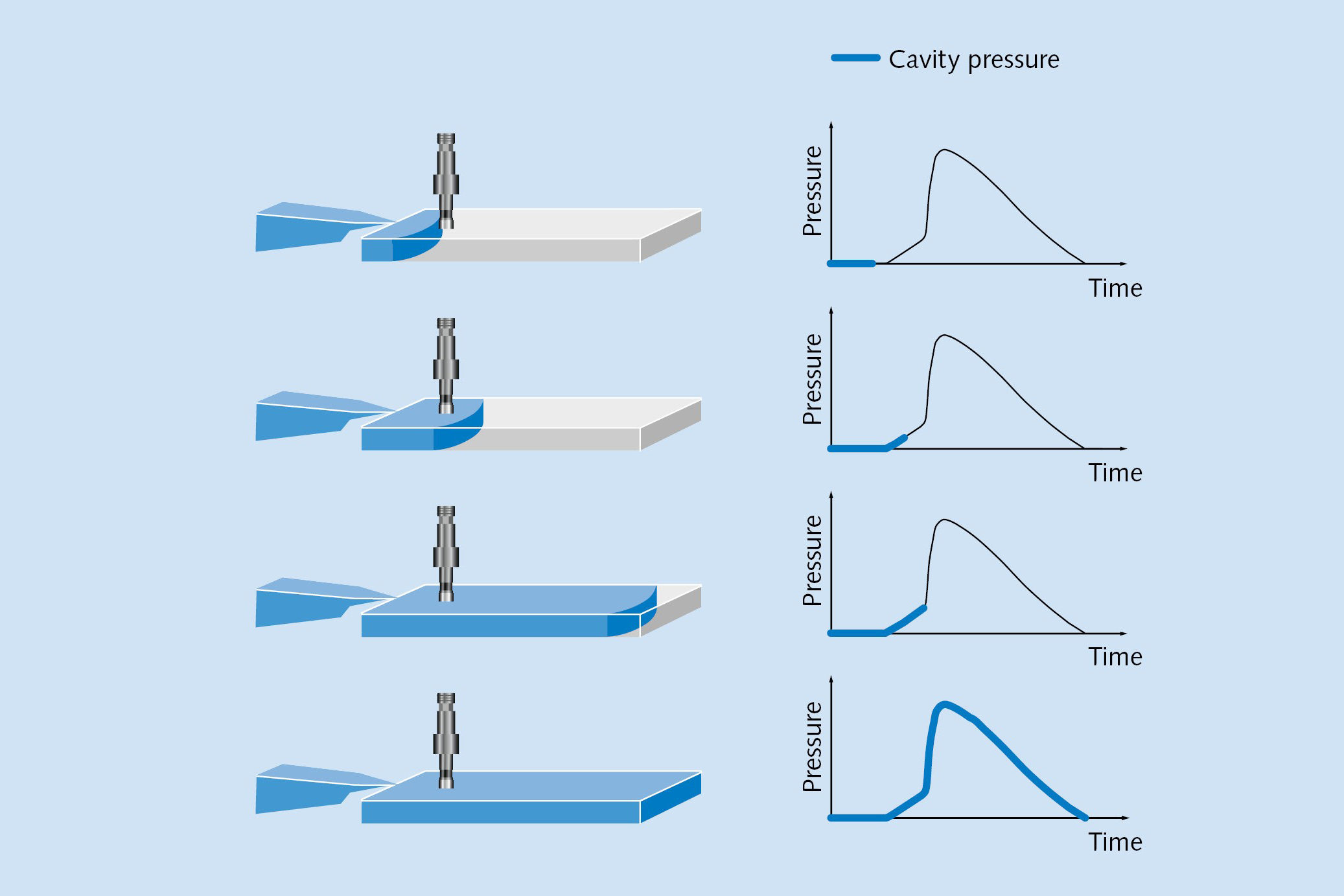

Kistler offers a wide range of different sensors – but selection of the right sensor is simple, because it is essentially based on the installation conditions in the mold. Piezoelectric measurement technology has a key advantage: it provides a sufficiently good signal over the entire measurement range (usually 0–2,000 bar). The measuring chain will only need to be adapted in case of very low pressures (in foaming processes, for example). To make installation as simple as possible, select the sensor with the largest possible geometric dimensions. The choice between a direct or indirect cavity pressure sensor depends on the basic design of the mold. For existing molds, a sensor behind an ejector is often the simpler option – but on the other hand, direct sensors offer more flexible positioning.

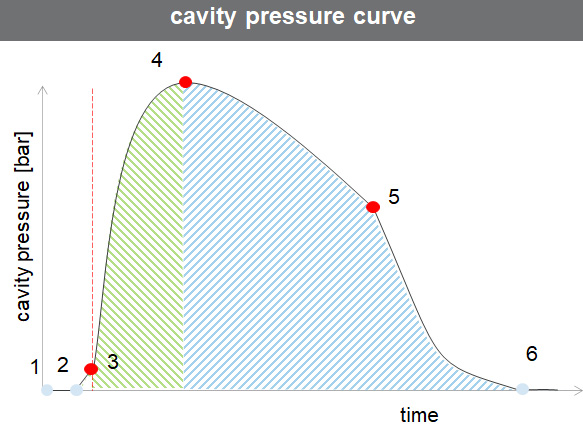

Reliable and accurate sensors are the foundation for effective process monitoring in injection molding. Measuring where the process actually takes place is the key to maximum process transparency. That’s why it’s our philosophy to acquire the critical process values of pressure and temperature directly in the injection mold. Our monitoring systems immediately show any deviations from the ideal state in the relevant process curves, so users can reliably predict the quality of the molded part – shot by shot.

Benefits:

- Efficient and targeted setup phase for new molds

- Minimum time and effort for tool startup

- Reliable monitoring of the injection molding process

- Highly informative individual documentation for each manufactured part

![Sensor-based efficiency gains for injection molders [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSHeading_1100x420/kistler_934-608_6691.webp)

![Sensors and systems for Quality monitoring and process control in injection molding [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-112e.webp)

![Technology and process know-how – the keys to success [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-733e.webp)