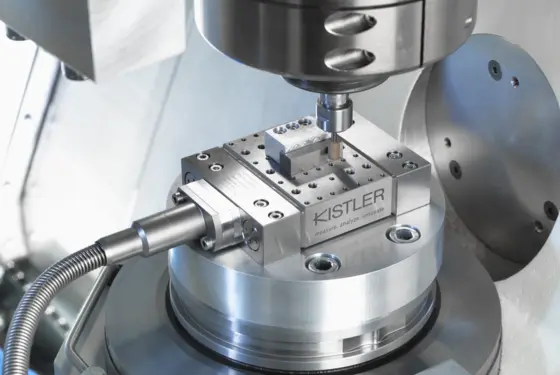

BIG KAISER uses a multicomponent dynamometer from Kistler to carry out objective comparison tests on cutting tools.

Winterthur, September 2021 – To perform objective comparison tests on tool holders, BIG KAISER uses a measuring chain from Kistler – comprising a dynamometer, laboratory charge amplifier and analysis software – for cutting force measurements. As well as providing support for ongoing product development, the results generate extra impetus for the sales and customer advisory teams.

BIG KAISER is a Swiss company that has achieved worldwide renown thanks to its high-performance precision tools. Founded back in 1948, Big Kaiser Precision Tooling Ltd. now offers a portfolio that includes boring, milling and turning tools as well as tool holders – products that are a byword for high precision and stability in the metal machining industry. 170 employees in Switzerland, Germany and the USA ensure that the company's products and systems meet the very highest standards.

They are used in high-tech sectors such as watch manufacturing, automobile production and aircraft construction, and also in the medtech sector. The production facility with its 120-strong workforce is located in Rümlang near Zurich. BIG KAISER is also a member of the global BIG DAISHOWA Group, headquartered in Osaka (Japan), which has 900 employees spread across the world.

![Reliable control of boring and milling processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-490e.webp)

![Bohr- und Fräsbearbeitung sicher im Griff [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-490d.webp)