Winterthur, October 2023 - With the new AkvisIO IME (Injection Molding Edition) data analysis software, Kistler is helping its customers take a further step towards the digitalization of injection molding: all of the data from machines and process monitoring systems like ComoNeo and ComoScout can now be visualized and analyzed synchronously and across processes.

In addition to suitable machines and tools, high-performance and transparent injection molding processes often require more in-depth optimization with sensors and continuous production monitoring. Moreover, when it comes to designing processes that are optimal over the long term, data management and data analysis play a decisive role: they are the missing, often underutilized, link in the value chain of modern plastics processing.

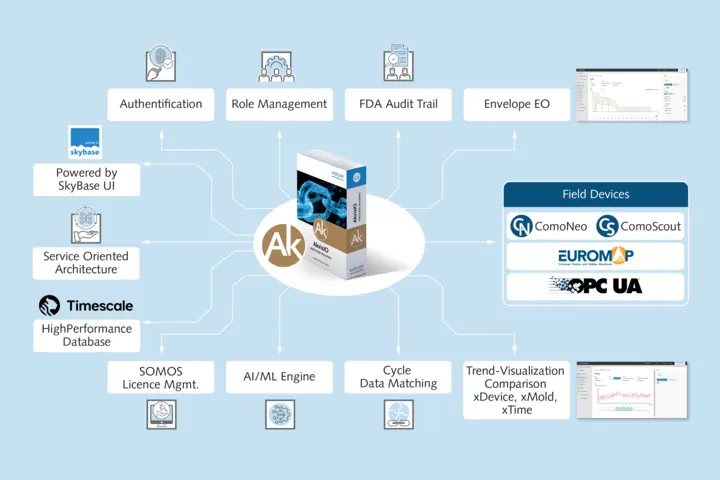

AkvisIO IME from Kistler bridges this gap and enables customers to manage and analyze data across devices and processes. The data analysis software for recording, storing and analyzing high-frequency sensor and machine signals during injection molding is intended for use by both process engineers and data scientists. It replaces the previous ComoDataCenter (CDC) data management solution from Kistler and provides a comprehensive analysis function including automatic data synchronization with all connected systems.

![Digitally optimized injection molding: the new AkvisIO data analysis software from Kistler [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-270e-10.23.webp)