Data that Kistler, as an expert in measurement technology, is capable of recording?

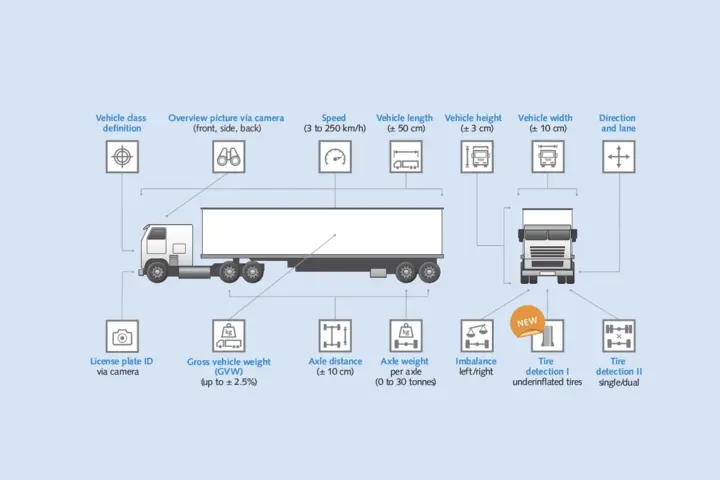

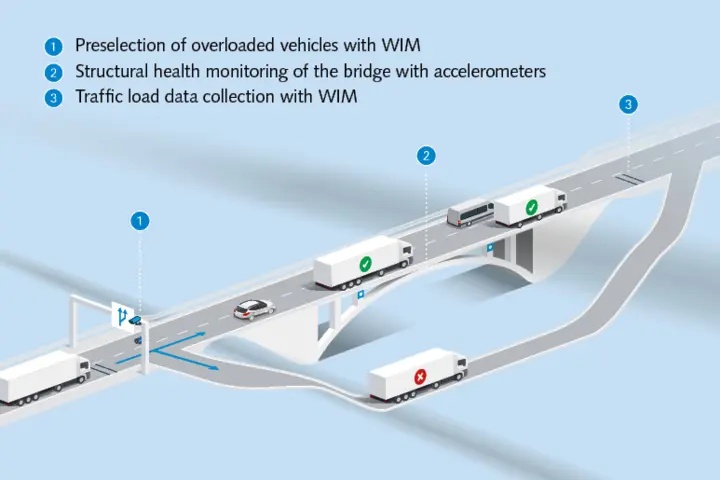

Christoph Klauser: Yes, our products can make a significant contribution during both condition monitoring and active control of traffic volumes. And, while we are on the issue of traffic volumes, our Weigh In Motion systems can record traffic data with great precision. This means that all vehicles approaching or crossing the bridge are checked. In addition to the weight of the vehicles, information on the transit time and the vehicle type, length or speed can also be recorded in this manner. Recording the actual traffic load also helps in the subsequent step when it comes to reliably calculating the remaining service life expectancy of a bridge, rather than only using load assumptions based on a standard.