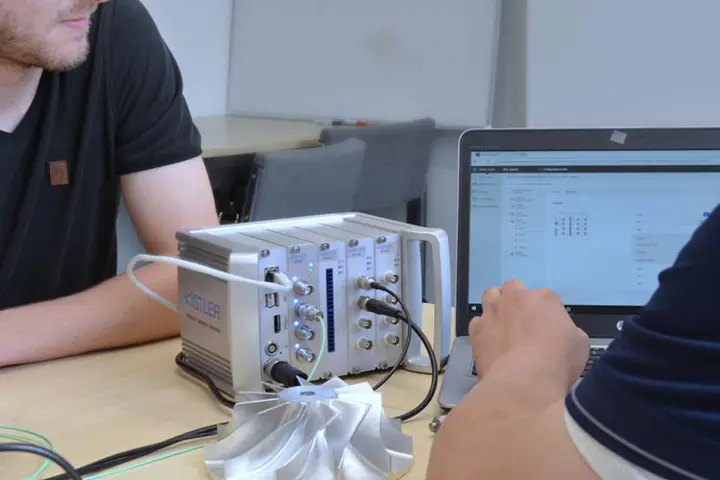

Kistler's KiDAQ modular integrated data acquisition system lets users explore new ground in the design of complex measuring chains commonly found in research and development. An initial look at the system and how it can be used in cutting force measurement was taken by the machine tool laboratory of RWTH Aachen University.

The Laboratory for Machine Tools and Production Engineering of RWTH Aachen is one of the Germany's leading research institutes in the machine tool sector. Four chairs are devoted to research in the fields of production systems and factory planning, the technology of manufacturing processes, process monitoring and quality management. Not only does the institute conduct basic research, it also cooperates with leading companies across the globe to foster innovation and blaze a trail into new technological worlds. Kistler's partnership with the laboratory dates back almost 50 years and stems from the high performance of the company's piezoelectric measurement technology.

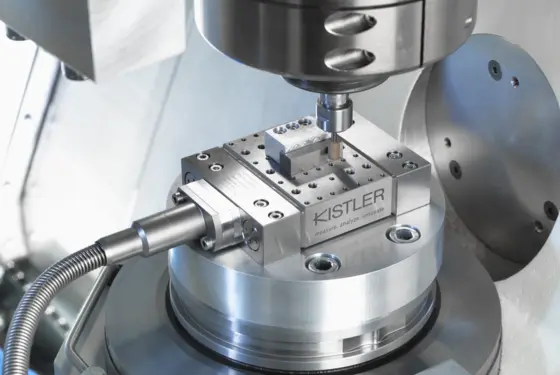

Given their high-precision, very wide measurement range (from a few newtons to a meganewton) –and high resilience even in demanding ambient conditions, piezoelectric (PE) sensors are predestined for implementation scenarios with high requirements. They are ideal for use in highly dynamic force measurements, such as on machine tools that mill grooves into turbine blades, The laboratory also uses PE dynamometers for combined force and torque measurements when conducting complex modal analyses.

![The entire measuring chain from a single source [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-121e.webp)